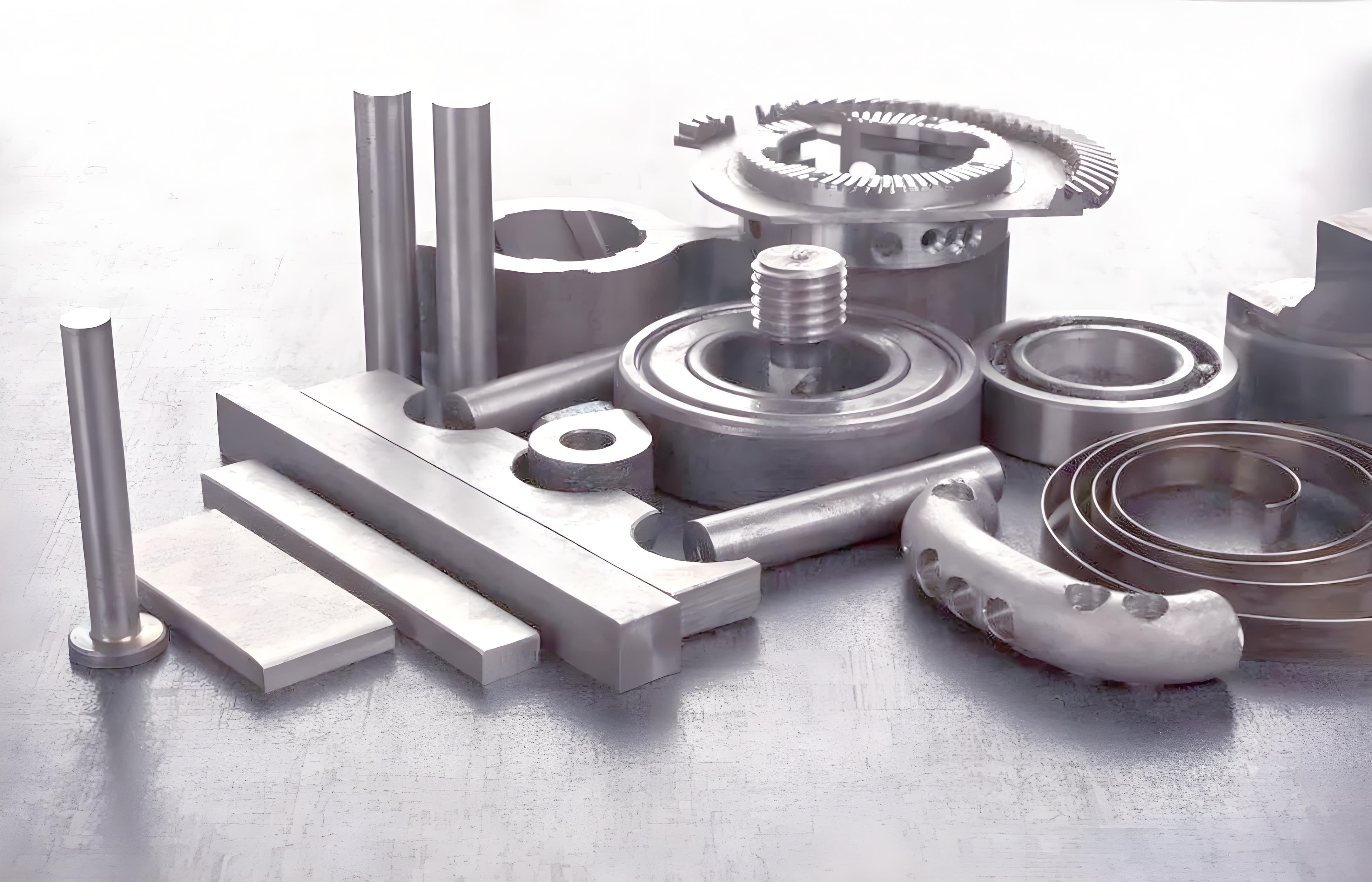

In the design phase of automated equipment, selecting the appropriate stainless steel grade is crucial. Using unsuitable materials can increase processing costs, extend delivery times, and even lead to long-term reliability risks.

Key Factors in Material Selection

Before selecting a stainless steel grade, it is important to clarify:

-

Load-bearing or non-load-bearing function

-

Environmental exposure (humidity, chemicals, washdown)

-

Precision and dimensional stability requirements

-

Production volume and cost targets

Common Stainless Steel Grades Used in Automation

1. Austenitic Stainless Steel – 304 / 316L

Most commonly used

-

Excellent corrosion resistance

-

Mature machining processes

-

Good surface finish options

Typical applications:

-

Machine covers and enclosures

-

Support brackets

-

Pipes and non-load-bearing structures

316L is preferred in more aggressive or frequently cleaned environments.

2. Martensitic Stainless Steel – 410 / 420

For wear resistance and hardness

-

Heat treatable

-

Higher hardness compared to austenitic grades

Typical applications:

-

Shafts

-

Pins

-

Wear components

Corrosion resistance is lower than 304/316 and should be evaluated carefully.

3. Precipitation Hardening Stainless Steel – 17-4PH

For high-strength automation components

-

High strength with good corrosion resistance

-

Good dimensional stability after proper heat treatment

Typical applications:

-

Load-bearing brackets

-

Critical connectors and mounts

Manufacturing note:

Heat treatment planning is essential to control distortion and final tolerances.

Common Material Selection Mistakes

-

Over-specifying strength, increasing machining cost

-

Ignoring machinability at the design stage

-

Underestimating heat treatment and post-processing impact

Design Recommendation

Collaborating with manufacturing partners early on can validate material selection from a manufacturability and cost perspective, reducing redesigns and delays later in the project.

Summary

The best stainless steel grade is not the strongest or most expensive, but the one that best meets the functional, environmental, and manufacturing feasibility requirements.

If you are developing or optimizing automated equipment components, please feel free to contact us. We can provide engineering support from material selection and processing technology to cost and delivery time.