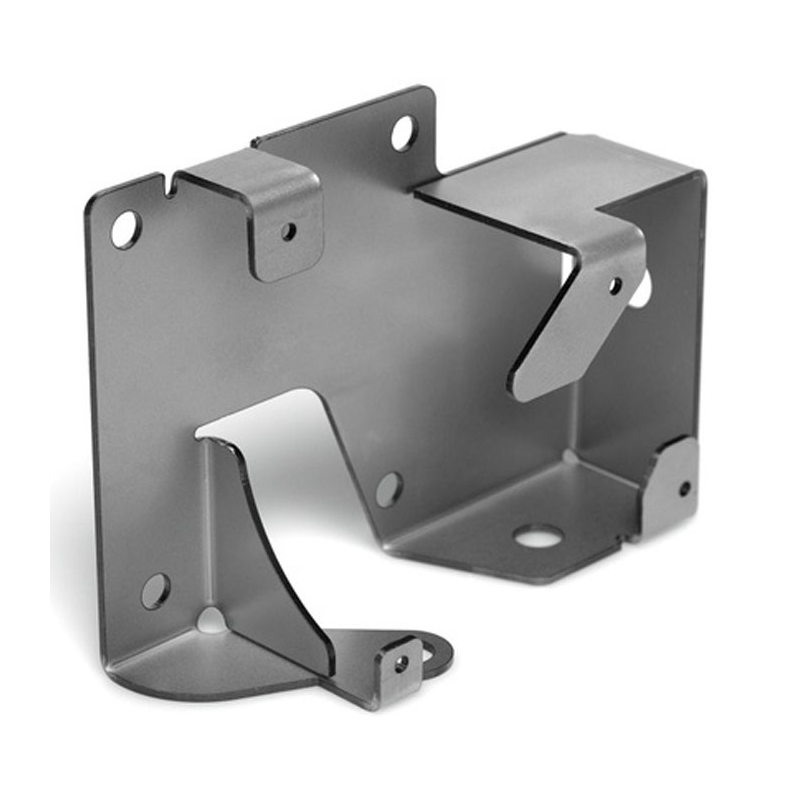

Common surface treatment methods after sheet metal processing

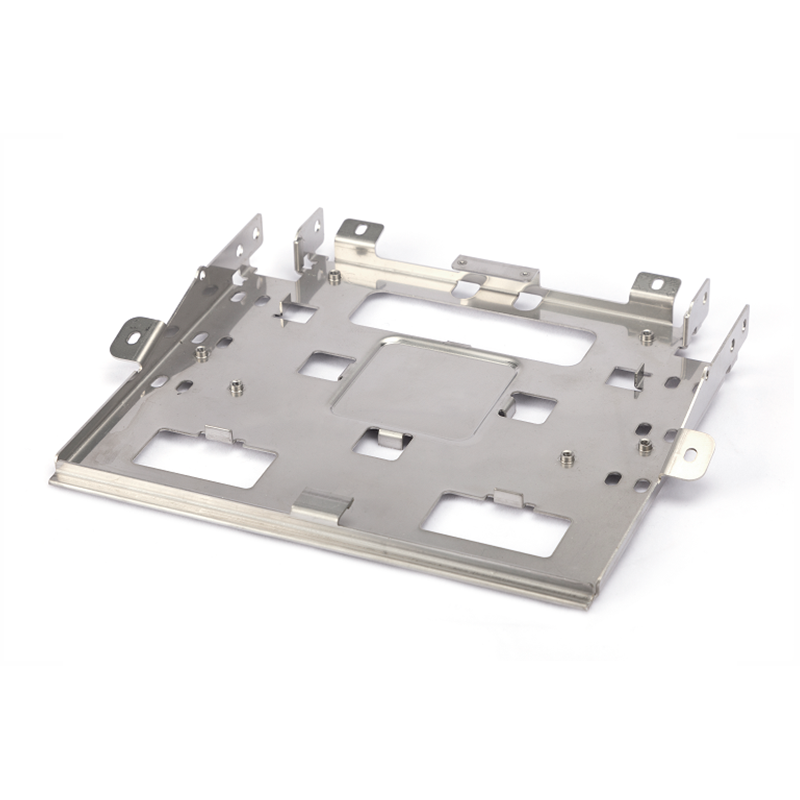

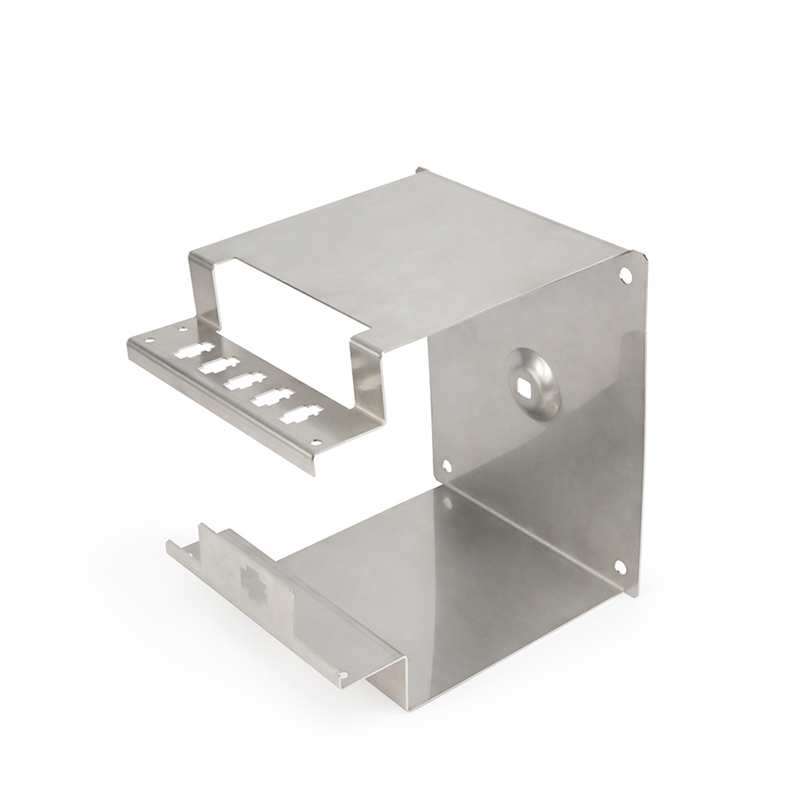

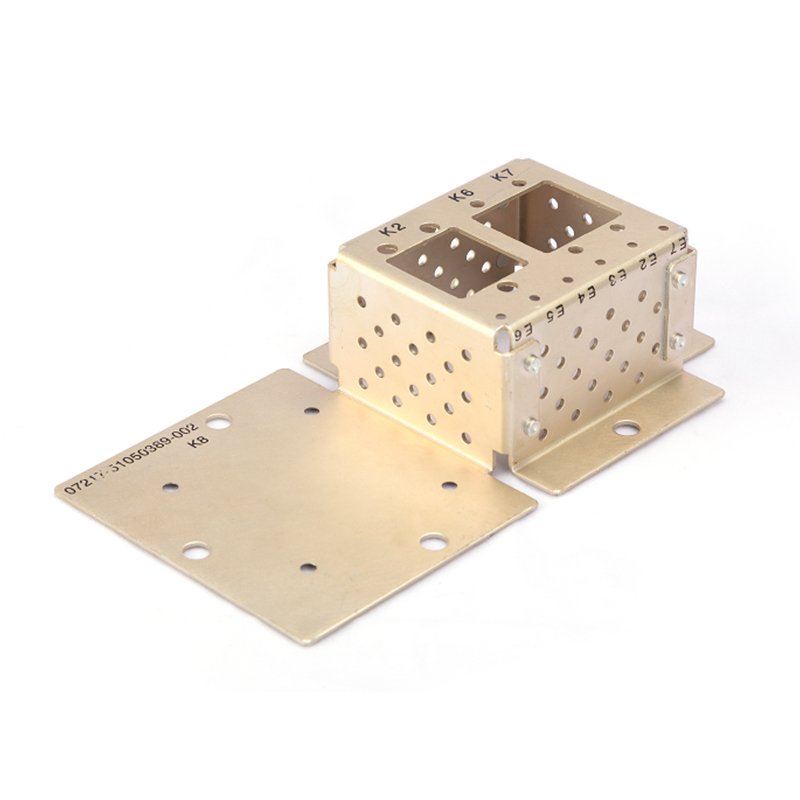

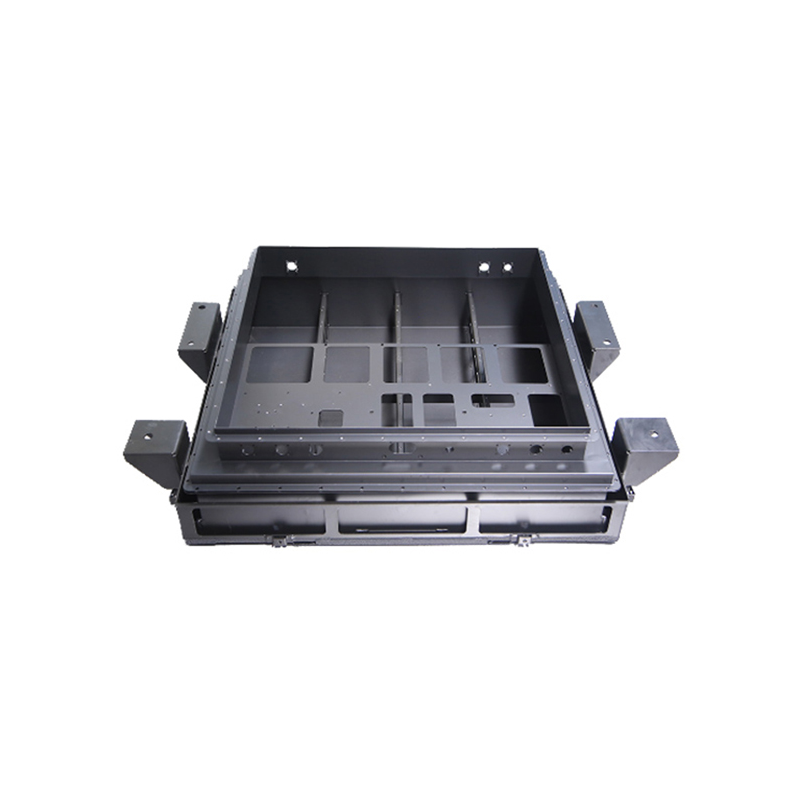

After completing basic processing procedures such as shearing, stamping, bending, and welding, sheet metal parts often need surface post-processing to meet customer requirements for performance,