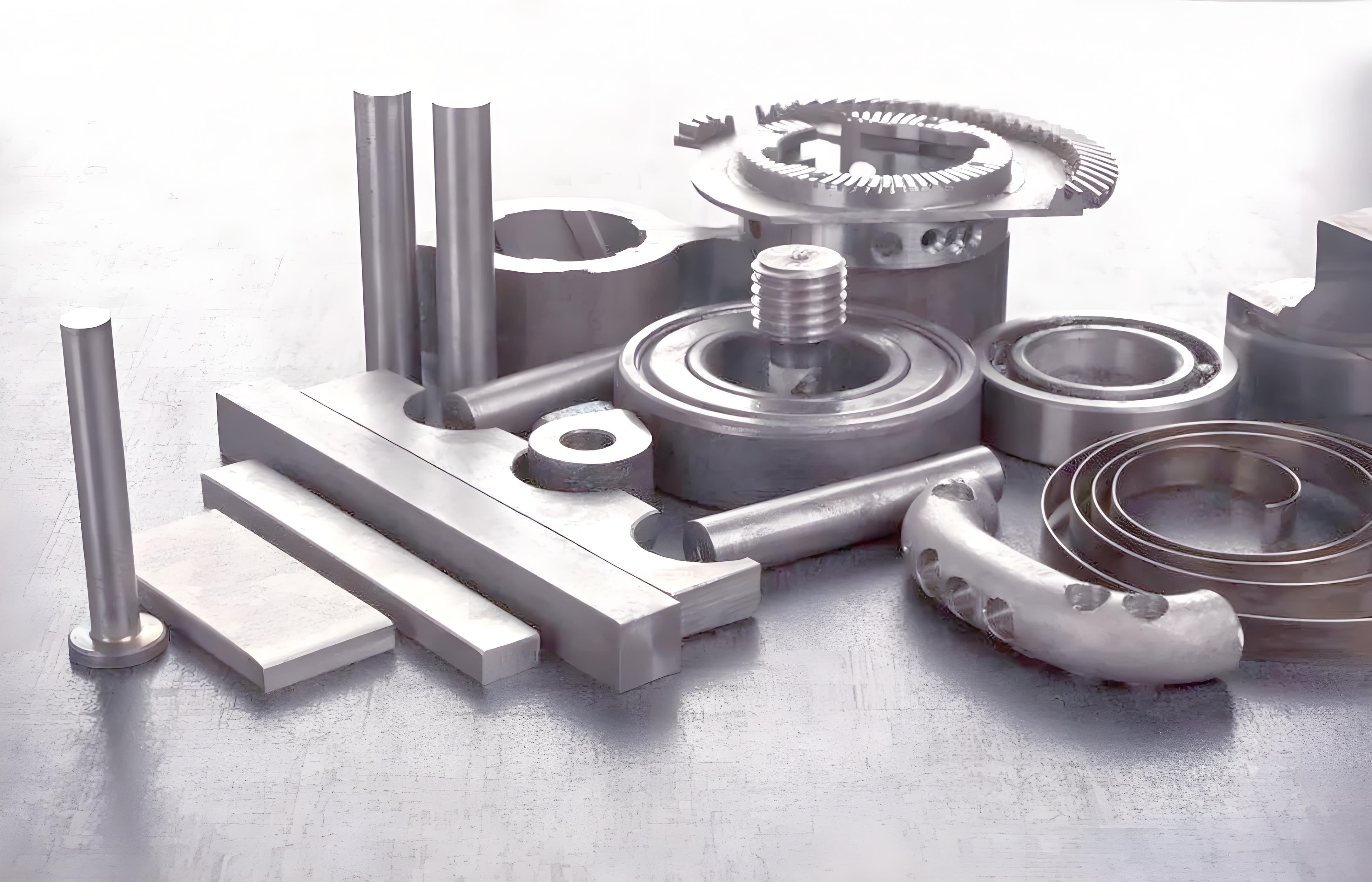

In manufacturing, even the absence of a single component can bring an entire production line to a standstill. Recently, we assisted a client in urgently ordering a precision-machined metal component crucial for final assembly. Thanks to our rapid engineering response and expedited overnight production capabilities, the client successfully avoided costly delays and delivered on time.

Client Challenge: Critical Component Missing Causes Assembly Line Shutdown

The client, an equipment manufacturer, discovered a critical custom component was missing during final assembly. Due to the component’s stringent dimensional tolerances and the lack of readily available substitutes, production immediately halted.

Key Challenges:

- Only three days remained until the client’s final delivery deadline.

- The missing component was critical to the machine’s functionality.

- The original supplier could not produce a replacement component in time.

- Any delays would result in high labor and operating costs.

Due to the assembly line shutdown, the client contacted us for urgent support.

Our Response: Expedited Overnight Machining with Comprehensive Quality Control

Upon receiving the drawings and specifications, we immediately initiated an emergency machining process.

1. Immediate Engineering Assessment

Our engineering team completed the following tasks in a short time:

- Drawing and tolerance analysis

- Tooling and fixture design

- Machining strategy and toolpath programming

- Material availability check

This allowed us to immediately begin production, avoiding wasting valuable time.

2. Overnight Production by Our Professional Night Shift Team

To meet the customer’s deadline, our night shift technicians immediately began production:

- Continuous roughing and finishing

- Perform in-process measurements to ensure dimensional accuracy

- Deburring and visual inspection before delivering the part to the quality assurance department

Despite the tight schedule, every step strictly adhered to quality standards.

3. Morning Inspection and Acceptance

At dawn, our quality control team performed the following tasks:

- Critical dimension verification

- Surface quality inspection

- Document preparation and inspection report

The part passed all measurements on the first attempt and was approved for shipment.

Arrange same-day shipment as quickly as possible.

After the customer confirmed the inspection results, we:

- Completed protective packaging

- Contacted the fastest international courier company

- Shipped the order that morning

The customer received the parts the next day and immediately resumed assembly, successfully fulfilling the delivery commitment.

Project Outcomes

This urgent project brought significant value to the customer:

- Avoided production line downtime

- Maintained the customer’s promised delivery schedule

- Avoided additional costs incurred due to delays

- Enhanced the customer’s confidence in our responsiveness and reliability

For our team, this case highlights our ability to balance speed, precision, and flexibility under tight time constraints.

Conclusion

A reliable machining partner is key to delivering critical orders on time. As a precision CNC machine tool manufacturer in China, we are committed to:

- Rapidly responding to engineering needs

- Stable and consistent machining accuracy

- Flexible scheduling for urgent projects

- Fast international shipping arrangements

Whether you need rapid prototyping or urgent machining support, our team is ready to help.

With the end of the year fast approaching, if you have any urgent projects requiring processing, please feel free to contact us. Our technical team is available 24/7 and will help you complete the required parts with the fastest possible delivery time.