Applications of Titanium Alloys in the Energy Sector

As equipment evolves towards higher performance, higher efficiency, and longer lifespan, the energy industry’s demands for materials are constantly increasing. Titanium alloys, due to their high strength, low density, corrosion resistance, high temperature resistance, and high fatigue resistance, are becoming an important material choice in these fields. The energy industry operates under extremely harsh conditions—high pressure, seawater corrosion, high temperatures, and chemically corrosive environments. Titanium alloys can provide the necessary durability, safety, and performance in these extreme environments.

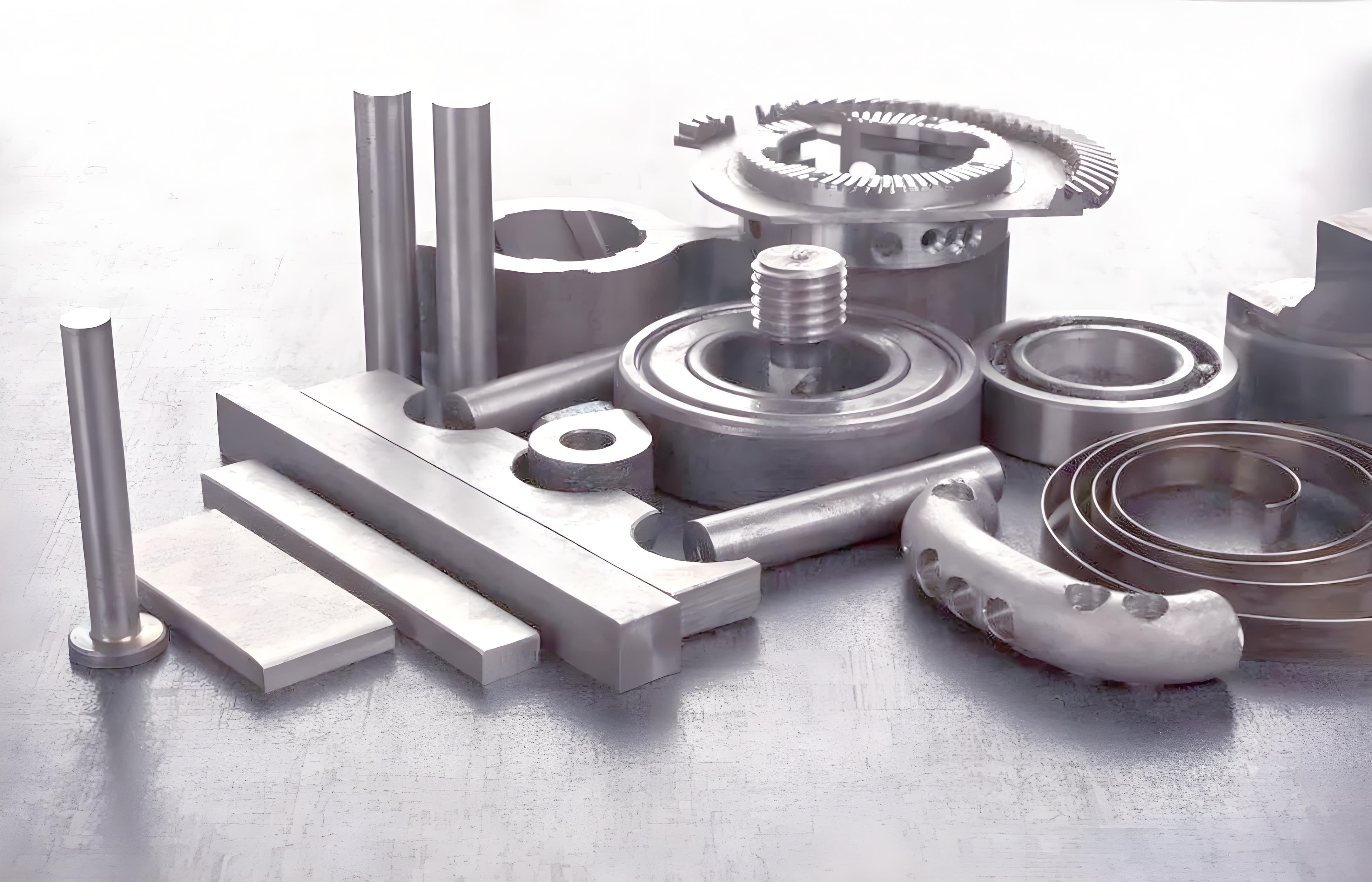

With years of experience in titanium processing, CS MOLDING helps global energy companies produce precision components with tight tolerances and short lead times.

The following are the main applications of titanium alloys in the energy sector:

1. Marine Engineering and Seawater Equipment

Titanium is one of the few metals that can completely resist seawater corrosion, making it indispensable in marine environments.

Typical applications include:

- Evaporators and condensers in seawater desalination systems

- Pipeline and valve assemblies for offshore platforms

- Subsea oil extraction systems

- Titanium can significantly reduce maintenance requirements and delay system aging.

CS MOLDING provides precision titanium components for desalination plants and offshore equipment integrators.

2. Oil and Gas Exploration

Oil and gas equipment often faces corrosive, high-pressure, and high-temperature environments. Titanium possesses the following properties that contribute to improved system safety and lifespan:

- Resistance to acid gas corrosion

- Resistance to high-pressure fluid fatigue

- Resistance to stress corrosion cracking

- Common titanium components include:

- Deep-sea drilling equipment

- High-pressure pipeline fittings

- Pump and compressor components

3. New Energy Equipment (Hydrogen Energy, Energy Storage, Renewable Energy)

Titanium alloys are increasingly widely used in new energy technology fields due to their high strength, low density, and resistance to hydrogen embrittlement.

Applications include:

- Hydrogen storage tanks and linings

- High-efficiency heat exchangers

- Cooling components in renewable energy systems

With the increasing global investment in hydrogen and clean energy, the demand for titanium continues to rise.

4. Nuclear Energy Systems

Nuclear energy systems require materials capable of reliable operation under high temperature, high pressure, and radiation environments. Titanium meets these stringent requirements.

Key components include:

- Nuclear heat exchanger tubing

- Cooling water piping

- High-strength structural fasteners

Titanium enhances system safety, efficiency, and long-term stability.

Why energy companies choose CS MOLDING for titanium machining:

- Proficient in Ti-6Al-4V, Grade 2, and other aerospace-grade titanium alloys

- Five-axis precision machining, capable of processing complex geometries

- Rapid prototyping and small-batch production

- Strict quality control (coordinate measuring machine, material traceability, surface treatment)

- Support for urgent projects; overnight machining services available.

With the end of the year fast approaching, if you have any urgent projects requiring processing, please feel free to contact us. Our technical team is available 24/7 and will help you complete the required parts with the fastest possible delivery time.