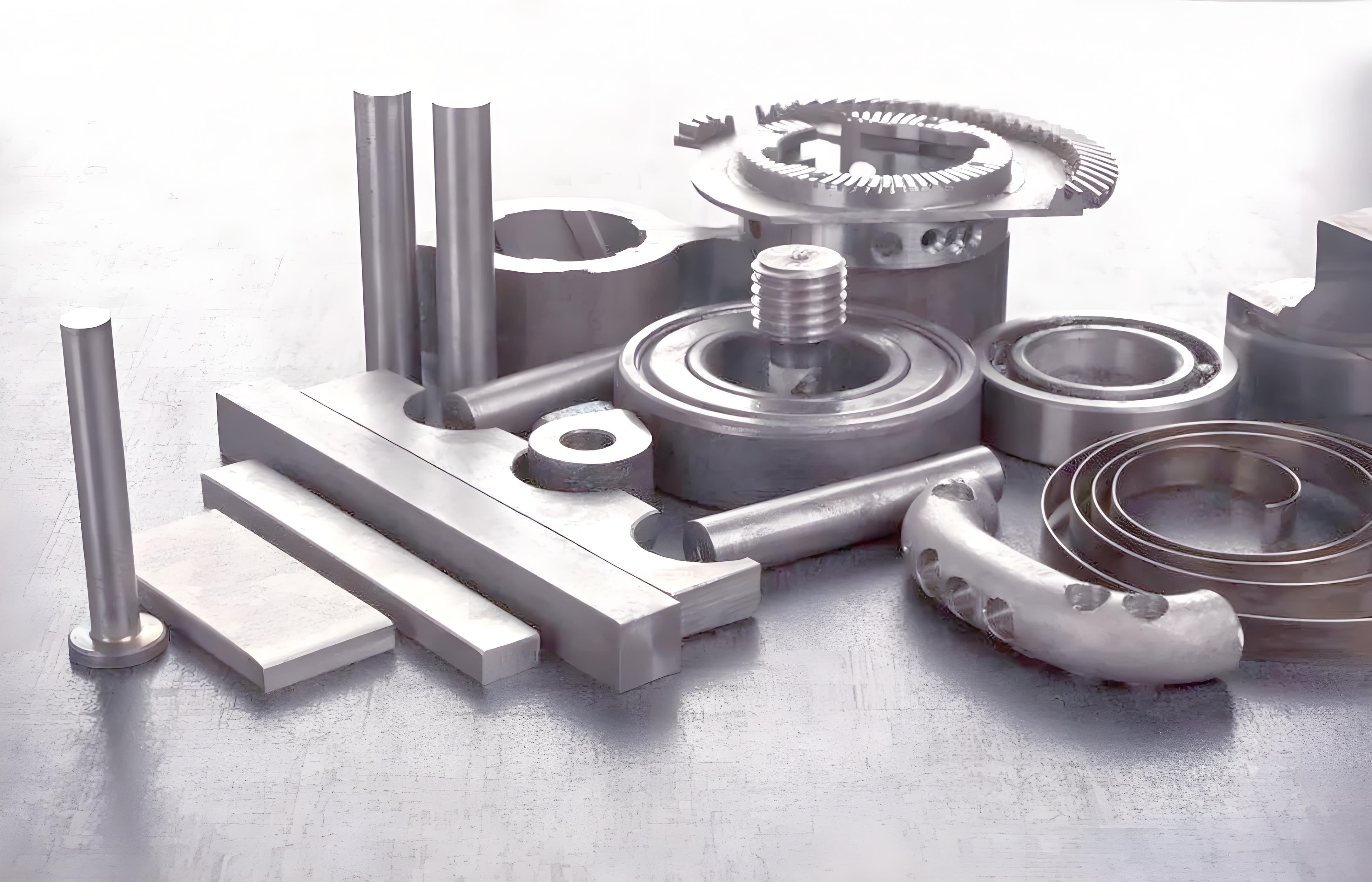

The aerospace industry is one of the most demanding in modern manufacturing. From small connectors to large structural components, every part must meet extremely high standards of precision, reliability, and traceability.

CS MOLDING has many years of experience providing high-precision CNC machining and sheet metal components for industries such as automation, robotics, and aerospace.

Our experience working with aerospace clients demonstrates that this sector pushes every aspect of machining to the extreme.

1. Ultra-tight tolerances and dimensional stability

In aerospace projects, tolerances are often specified within ±0.005 mm or less, and consistency is uncompromising.

Machining parts such as housings, brackets, or fixtures requires not only high-end five-axis equipment but also:

Strict shop floor temperature control

Tool wear monitoring and compensation

In-process inspection to ensure accuracy

We utilize advanced measurement systems and real-time process feedback to ensure that every part meets specifications, even during long production runs.

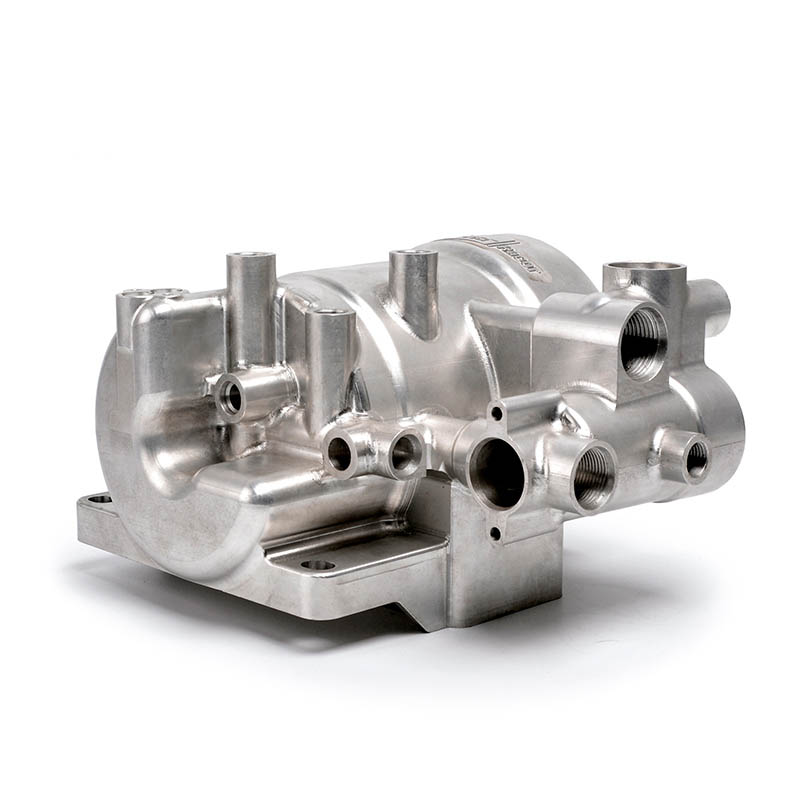

2. Complex structures and multi-axis machining

Aerospace components often feature angled holes, curved surfaces, and deep cavities, which pose challenges both in programming and cutting stability. Our engineers rely on multi-axis machining centers and simulation-based CAM programming to optimize tool paths and eliminate collision risks.

By combining CNC milling, turning, and precision sheet metal processing, we can complete complex assemblies with fewer setups and shorter lead times.

3. Aerospace Materials: Titanium, Inconel, and Others

Aerospace customers prefer advanced alloys such as titanium, Inconel, and 7075 aluminum to optimize strength and weight.

These materials are difficult to machine for the following reasons:

Titanium alloys are hard and have poor thermal conductivity

Inconel alloys are work-hardening

Aluminum structural parts require a high surface finish

We continuously test tool grades, coatings, and cutting parameters to achieve the optimal balance between surface quality and cost-effectiveness, especially for prototyping and low-volume production.

4. Quality, Traceability, and Documentation

Every aerospace project requires documented process controls—from raw material certification to final inspection reports. At CS MOLDING, we ensure full part traceability through:

Material and batch tracking

Coordinate measuring machine (CMM) inspection reports

Surface finish and process records

Our internal quality system complies with ISO9001 standards and can be customized to meet AS9100 documentation requirements.

5. From Prototype to Production

Aerospace customers often begin with small batch prototypes for design validation.

Our rapid prototyping capabilities—in-house CNC machining, sheet metal fabrication, and surface finishing—allow for rapid iterations before moving to series production.

This integrated workflow helps shorten lead times and ensures consistency between prototype and production.

6. Looking Ahead

The aerospace industry’s move toward lightweight materials, hybrid propulsion systems, and autonomous flight means precision manufacturing will become even more challenging.

At CS MOLDING, we see this as an opportunity to apply our expertise in CNC machining and metal fabrication to support global aerospace innovation.

Whether it’s a complex aluminum housing, a titanium bracket, or a precision sheet metal enclosure, we are committed to delivering reliable, high-quality, and fully traceable components on time and to specification.