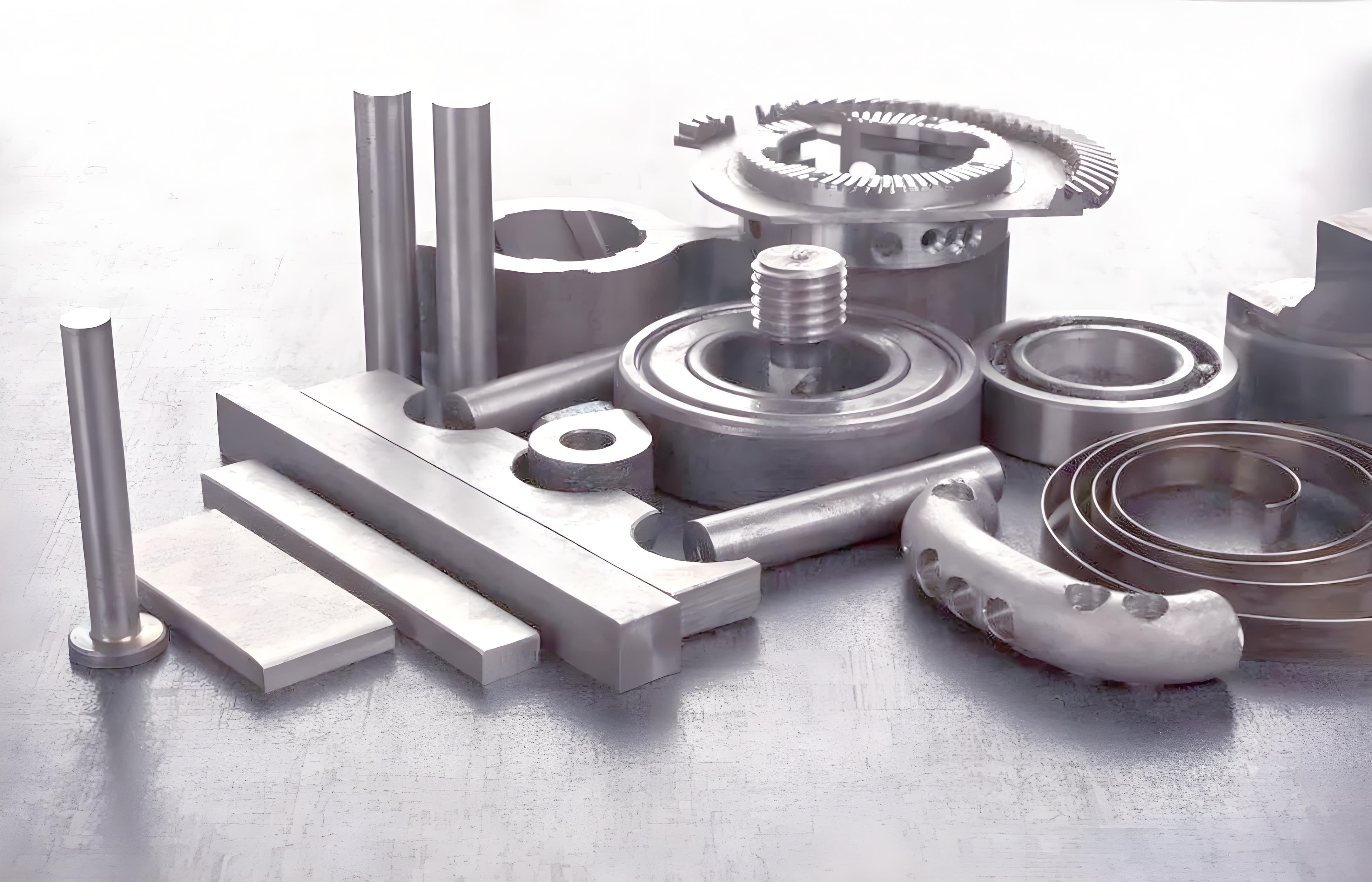

In insert molding technology, the “plastic matrix + metal insert” combination is the most popular. Plastic, with its advantages of lightweight, easy molding, and manageable costs, provides the component’s primary structure, while metal inserts compensate for plastic’s shortcomings in strength, conductivity, and wear resistance. This combination offers both cost-effectiveness and high performance, and is widely used in the automotive, electronics, medical, and home appliance sectors. As a company specializing in precision molding, CS Molding has customized “plastic + metal” insert solutions for thousands of projects and is familiar with the compatibility of different metal inserts with plastic matrices. Below, we will analyze the key application points using clear classifications and case studies.

I.Core Metal Inserts: Choose Based on Needs

1.Brass Inserts (H62/H65)

Key Advantages: Excellent electrical conductivity, wear resistance, and easy threading.

Compatible Plastics: PA66 (load-bearing), PBT (medium-temperature), ABS (low-cost).

Typical Applications: Electronics (router Ethernet ports, charger terminals), home appliances (washing machine threaded posts), automotive (sensor terminals).

2.Stainless Steel Inserts (304/316)

Key Advantages: 304 offers corrosion resistance and temperature resistance (≤600℃); 316 is acid/alkali resistant and biocompatible (for medical use).

Compatible Plastics: PPS (high-temperature), medical-grade PC (human contact), PA66 (outdoor load-bearing).

Typical Applications: Medical (infusion set connectors), automotive (engine compartment sensors), outdoor (PV inverter terminals).

3.Aluminum Alloy Inserts (6061/5052)

Key Advantages: Lightweight (density 2.7g/cm³), low cost, and easy processing.

Compatible Plastics: ABS (automotive interiors), PP (consumer electronics), PA6 (medium load-bearing).

Typical Applications: Automotive (interior panel fasteners), consumer electronics (laptop hinges), power tools (handle supports).

4.Special Alloy Inserts

Titanium Alloy (TC4): Corrosion-resistant and biocompatible; compatible with PEEK. Used in dental implants and aerospace sensors.

Zinc Alloy (Zamak 3): Easy to mold and low-cost; compatible with ABS. Used in small home appliance buttons.

II.Plastic Matrix Selection Logic: “Matching the Metal + Adapting the Scenario”

Plastic Matrix | Key Characteristics | Compatible Metals | Suitable Scenarios |

PA66 | High strength, temp-resistance ≤150℃ | Brass, Stainless Steel | Load-bearing parts (threaded posts, brackets) |

PPS | Temp-resistance ≤220℃, acid/alkali resistant | Stainless Steel, Titanium Alloy | High-temperature/corrosive parts (engine compartment components) |

PC | Transparent, impact-resistant | Medical Stainless Steel, Brass | Transparent parts (lamp covers), medical equipment |

ABS | Easy to mold, low cost | Aluminum Alloy, Zinc Alloy | General parts (interiors, small home appliance housings) |

III.Industry Applications: Concise Matching

Industry | Core Requirements | Recommended Material Combinations |

Automotive | Lightweight, temp-resistance | Interiors: Aluminum Alloy + ABS; Engine Compartment: Stainless Steel + PPS |

Electronics | Conductivity, insulation | Conductive: Brass + PC; Insulative: Stainless Steel + PPS |

Medical | Safety, corrosion resistance | Fluid Contact: 316 Stainless Steel + Medical PC; Implants: Titanium Alloy + PEEK |

Home Appliances | Low cost, durability | Threaded Posts: Brass + PA66; Moisture-prone Parts: Stainless Steel + PP |

IV. CS Molding: Solving the Core Challenges of “Plastic + Metal” Insert Molding

lthough “Plastic + Metal” insert molding offers significant advantages, it is prone to three major issues: insert loosening, plastic cracking, and surface flash. The key is to address differential thermal shrinkage and insufficient bonding strength. CS Molding addresses these challenges through customized solutions:

1. Insert Pretreatment Technology:

To address weak metal-plastic bonding, insert surface treatment is performed. For brass/stainless steel, pickling and roughening is performed (to improve roughness), while for aluminum alloy, sandblasting and silane treatment is performed (to enhance adhesion). This can improve bonding strength by 30%-50%.

2. Process Parameter Optimization:

To address differential thermal shrinkage, injection molding parameters are adjusted based on the material. For example, for a brass insert + PA66 combination, preheating the insert (80-100°C) and then molding at a low temperature (250-260°C) are used to reduce plastic cooling shrinkage stress and prevent cracking.

3. Precise Positioning and Inspection:

Customized positioning tooling ensures insert positioning accuracy (±0.01mm) to prevent misalignment. Finished products undergo tensile testing (to ensure inserts remain intact), ultrasonic testing (to detect internal voids), and salt spray testing (to verify corrosion resistance) to ensure compliance.

CS Molding has extensive processing experience and can precisely match metal inserts to plastic substrates based on your application needs, optimizing process parameters and avoiding trial and error. If your project requires a “plastic + metal” insert solution, contact us today to discuss the optimal manufacturing solution.