Choosing the right manufacturing process is crucial in the transition from rapid prototyping to mass production. Of all available methods, injection molding stands out as the optimal solution for mass-producing high-quality plastic parts due to its efficiency and repeatability.

This article will explore the definition, working principle, advantages, and why injection molding is the final step in mass production after processes such as vacuum casting or CNC machining.

1. What is Injection Molding?

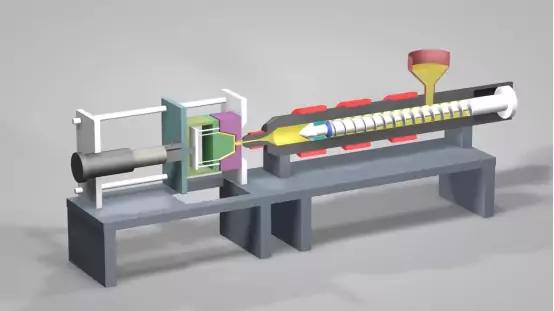

Injection molding is a manufacturing process that injects molten thermoplastic into a precision-machined mold under high pressure. After cooling and solidification, the finished part is removed from the mold for assembly or final use.

This method is widely used for the mass production of plastic parts requiring tight tolerances, consistent quality, and high surface finishes. Common applications include automotive parts, medical devices, and electronic housings.

2. Injection Molding Process Flow

The injection molding cycle consists of four main stages:

- Mold Closure – Securely closing the two halves of the mold.

- Injection – Injecting molten plastic into the mold cavity.

- Cooling – The plastic cools and solidifies into the desired shape.

- Ejection – Ejecting the finished part; the cycle repeats.

Each cycle can be completed in seconds or minutes, depending on the material and part geometry, making it efficient for mass production.

3. Injection Molds

Molds, also known as tools, are the core of the injection molding process. Their precision directly affects the quality, accuracy, and repeatability of each molded part.

Injection molds are typically made of the following materials:

- Aluminum molds – Economical and ideal for prototyping or small-batch production.

- Steel molds – Durable and suitable for long-term, high-volume production.

Modern CNC machining and electrical discharge machining (EDM) technologies ensure that molds are manufactured with micron-level precision and excellent surface finish.

4. Advantages of Injection Molding

| Feature | Benefit |

|---|---|

| High Efficiency | Capable of producing thousands of identical parts quickly. |

| Excellent Surface Finish | Produces smooth, detailed surfaces with minimal post-processing. |

| Material Versatility | Works with ABS, PC, PP, Nylon, TPE, and other thermoplastics. |

| Dimensional Accuracy | Delivers consistent parts with tight tolerances. |

| Scalability | Ideal for small-batch pilot runs and full-scale mass production. |

5. From Prototype to Mass Production

Injection molding is the final stage of the product development process.

After prototyping via vacuum casting, 3D printing, or CNC machining, engineers typically move to injection molding after the design is fully validated.

This transition ensures:

- Reliable product quality

- Shorter time-to-market

- Reduced unit cost in mass production

Ultimately, a seamless transition from prototype validation to full-scale production.

6. Applications of Injection Molding

Injection molding is a core process in many industries, including:

- Automotive—Interior and exterior trim, clips, connectors, and housings.

- Medical Devices—Housings, disposable components, and covers.

- Consumer Electronics—Housings, keyboards, and structural plastic parts.

- Industrial Equipment—Machinery housings, handles, and clamps.

It remains the preferred method for mass-producing complex plastic parts with high strength and high repeatability.

7. CS MOLDING – Precision Injection Mold Manufacturing

CS MOLDING specializes in precision CNC machining, injection mold design, and plastic injection molding services to meet the needs of both small-batch and high-volume production.

Our team provides comprehensive support to our clients throughout the product lifecycle – from prototyping and mold making to injection molding production.

We ensure that every part meets the highest standards of precision, consistency, and cost-effectiveness.

Whether you need rapid prototyping, prototyping, or production-grade injection molds, CS MOLDING offers tailored solutions to help you accelerate your time to market.