In the consumer electronics sector, from mobile phones and laptops to smart wearables, the prevalence of metal bodies and precision components is inseparable from CNC machining technology. This technology, with its high precision and high stability, has become a core force driving product upgrades. As a leading precision manufacturing service provider, CS Molding continues to provide consumer electronics brands with one-stop production solutions, from prototyping to mass production. Learn how CS Molding uses high-precision CNC machining to create smartphone frames, smartwatch components, and more, improving industry quality.

I.How CNC Works and Its Advantages

1.CNC machining transforms digital designs into physical parts using computer-controlled tools. Key Steps:

①3D Modeling: Designers create 3D models using software such as SolidWorks.

②Programming: Engineers create tool paths and cutting parameters.

③Multi-Axis Machining: 3-5 axis machines mill, drill, and shape metal.

④Finishing: Polishing or anodizing enhances appearance and durability.

2.CNC’s strengths are clear:

①Superior Precision: Tolerances as tight as ±0.01mm meet consumer electronics’ demands for miniaturization and precision.

②Complex Shaping: It creates curves, thin walls, and micro-holes—like antenna slots in phone frames—hard to achieve with traditional methods.

③Consistent Mass Production: Standardized processes and automation ensure 95%+ yield rates across batches

II.Applications of CNC in Electronics

1.Smartphones and Tablets

Apple first used CNC technology for the iPhone’s all-metal frame, which was carved from a single block of aluminum. This not only improved strength but also resolved signal issues associated with milling antenna slots.

CS Molding excels in this area. Its five-axis machines can process titanium and stainless steel, efficiently creating finely cut phone frames.

2.Smart Wearables: Balancing Miniaturization & Aesthetics

Smartwatch metal cases demand extreme precision. CNC carves intricate details in tiny spaces—like the mirrored finish of Apple Watch’s stainless steel case, achieved via precision grinding and polishing.

CS Molding’s HL530 3-head engraving machine, designed for 3C parts, achieves micron-level precision on small components like watch crowns and strap buckles, even with custom engravings.

3.Laptops: Merging Slim Design & Performance

High-end laptops rely on CNC machining to achieve their ultra-thin aluminum alloy designs. For example, the Huawei MateBook X Pro’s chassis is only 14.6mm thick, thanks to CNC milling that removes over 90% of the material while preserving critical structural supports.

CS Molding’s dual-channel HL432G4 precision engraving machine can process two workpieces simultaneously, significantly improving the production efficiency of laptop mid-frames and meeting the brand’s demand for rapid iteration.

III.CS Molding’s absolute advantage in this field

As a global leader in precision machining, CS Molding’s technological advantages in the consumer electronics sector are reflected in the following aspects:

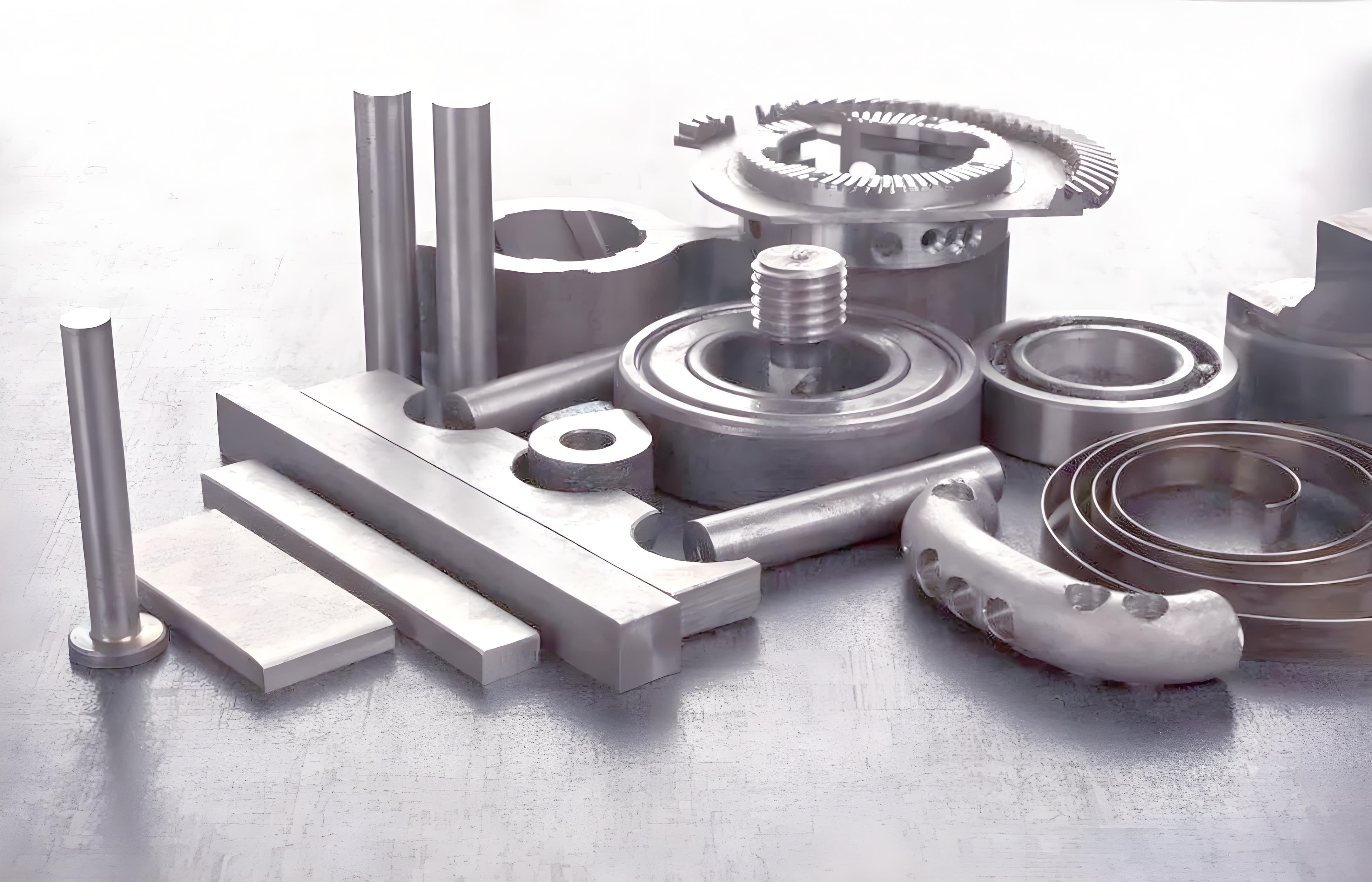

1.Advanced Equipment Cluster: CS Molding boasts over 70 high-precision CNC machines, including three-, four-, and five-axis machining centers, as well as high-speed drilling and tapping centers and specialized engraving machines, capable of meeting machining requirements of varying complexity.

2.Complex Material Processing Capabilities: CS Molding has developed specialized cutting parameters and tool combinations for difficult-to-machine materials like titanium alloys. Through adaptive control technology and real-time tool detection, the machining yield of titanium alloy mid-frames has been increased to over 92%.

3.Full-Process Quality Control: From incoming raw materials to finished product delivery, we adhere to stringent inspection standards, including three-dimensional coordinate measurement, surface roughness testing, and stress testing, to ensure every product meets customer requirements.

4.Quick Response and Flexible Production: Through modular design and automated production lines, we achieve a seamless transition from prototype development to mass production, reducing lead times to as little as seven working days.

IV.Choose CS Molding as a Trusted Partner

CNC machining has elevated the quality of consumer electronics, making them more stylish, robust, and reliable. CS Molding is leading this trend, employing cutting-edge technology to deliver precision and speed. As electronics continue to evolve, CS Molding remains committed to creating the next generation of devices.

Looking for a trusted, long-term partner? Contact us today to receive your customized solution.