Civil aerospace components—like parts for commercial planes, private helicopters, or civil satellites—need materials that balance safety, efficiency, and durability. Two of the most common choices are titanium alloy and stainless steel. Each has unique strengths, and picking the right one depends on the component’s job and your project goals. At CS Molding, we help clients select and process these materials for non-military civil aerospace parts. Let’s break down their differences in simple terms.

I.Core Traits of Titanium Alloy and Stainless Steel

To compare the two, we start with their basic properties—these shape how they perform in aerospace use:

1.Titanium Alloy Key Traits

1.1Lightweight: It is about 40% lighter than stainless steel of the same size. This is a big plus for aerospace, where less weight means lower fuel use or easier satellite launches.

1.2 High strength-to-weight ratio: It is almost as strong as stainless steel but with far less mass. It does not bend or break easily under pressure.

1.3 Strong corrosion resistance: It does not rust or degrade in harsh environments—like high-altitude moisture, salt air over oceans, or space’s vacuum and radiation.

1.4 Heat tolerance: It stays strong at temperatures up to 600°C, and does not become brittle in extreme cold (down to -250°C).

2.Stainless Steel Key Traits

2.1 High raw strength: It is generally stronger in pure force than most titanium alloy grades. It can handle heavy loads without deformation.

2.2 Low cost: Stainless steel is cheaper to source than titanium alloy, making it a budget-friendly option for many components.

2.3 Easy to process: It is simpler to cut, mold, and shape than titanium alloy, which can reduce manufacturing time and costs.

2.4 Good corrosion resistance: It resists rust in most environments, though not as well as titanium alloy in extreme or long-term harsh conditions.

II.Performance Comparison for Civil Aerospace Use

Let’s look at how the two materials stack up in key aerospace-focused areas:

| Trait | Titanium AlloyStainless Steel | Stainless Steel |

| Weight | Very light (cuts fuel/launch costs) | Heavy (adds to fuel use for planes) |

| Corrosion Resistance | Excellent (ideal for long-term use in harsh environments) | Good (works for standard conditions, not extreme space/salt air) |

| Strength-to-Weight Ratio | Outstanding (best for efficiency-focused parts) | Moderate (strong but heavy) |

| Heat/Cold Tolerance | Excellent (handles space/engine heat) | Good (works for standard temp ranges, less for extreme cold/heat) |

| Cost | High (material and processing) | Low (affordable for bulk or low-budget projects) |

| Processing Difficulty | High (needs specialized tools) | Low (easy to machine with standard equipment) |

III.Best Civil Aerospace Applications for Each Material

1.Titanium Alloy: Best for Efficiency and Extreme Conditions

Titanium alloy shines when lightweight and durability are top priorities:

1.1 Commercial airplane parts: Wing support brackets, hydraulic system tubes, and engine casing components. Its light weight cuts the plane’s total mass, lowering fuel consumption by 5-10% for long flights.

1.2 Civil satellite components: Satellite frame supports, solar panel mounts, and propulsion system fuel lines. Its light weight makes launches cheaper, and its corrosion resistance lets it last 15-20 years in space.

1.3 Private helicopter parts: Rotor blade hinges and landing gear pins. Its strength and lightness keep the helicopter agile and reduce wear on the engine.

2.Stainless Steel: Best for Cost and Heavy Loads

Stainless steel is the go-to for budget projects and components that need raw strength:

2.1 Commercial plane interior parts: Seat frame supports, overhead bin hinges, and cabin wall brackets. These parts need strength but do not impact the plane’s overall weight much, so stainless steel’s lower cost is a big benefit.

2.2 Helicopter landing gear frames: The gear must support the helicopter’s full weight on landing. Stainless steel’s high raw strength handles this load reliably at a lower cost than titanium alloy.

2.3 Civil drone components: Drone body frames and propeller shafts for large cargo drones. Stainless steel is cheap and easy to process, making it ideal for bulk drone production.

IV.Key Factors to Choose Between Them

When picking a material for your civil aerospace component, ask these three simple questions:

1.Does weight matter most? If yes, pick titanium alloy (for fuel efficiency or satellite launches).

2.Is budget a top priority? If yes, stainless steel is the better choice (for parts where weight is not critical).

3.Will the part face extreme conditions? If it will be in space, over oceans, or near hot engines, titanium alloy’s corrosion and heat resistance make it the safer option.

V.CS Molding: Your Civil Aerospace Material Partner

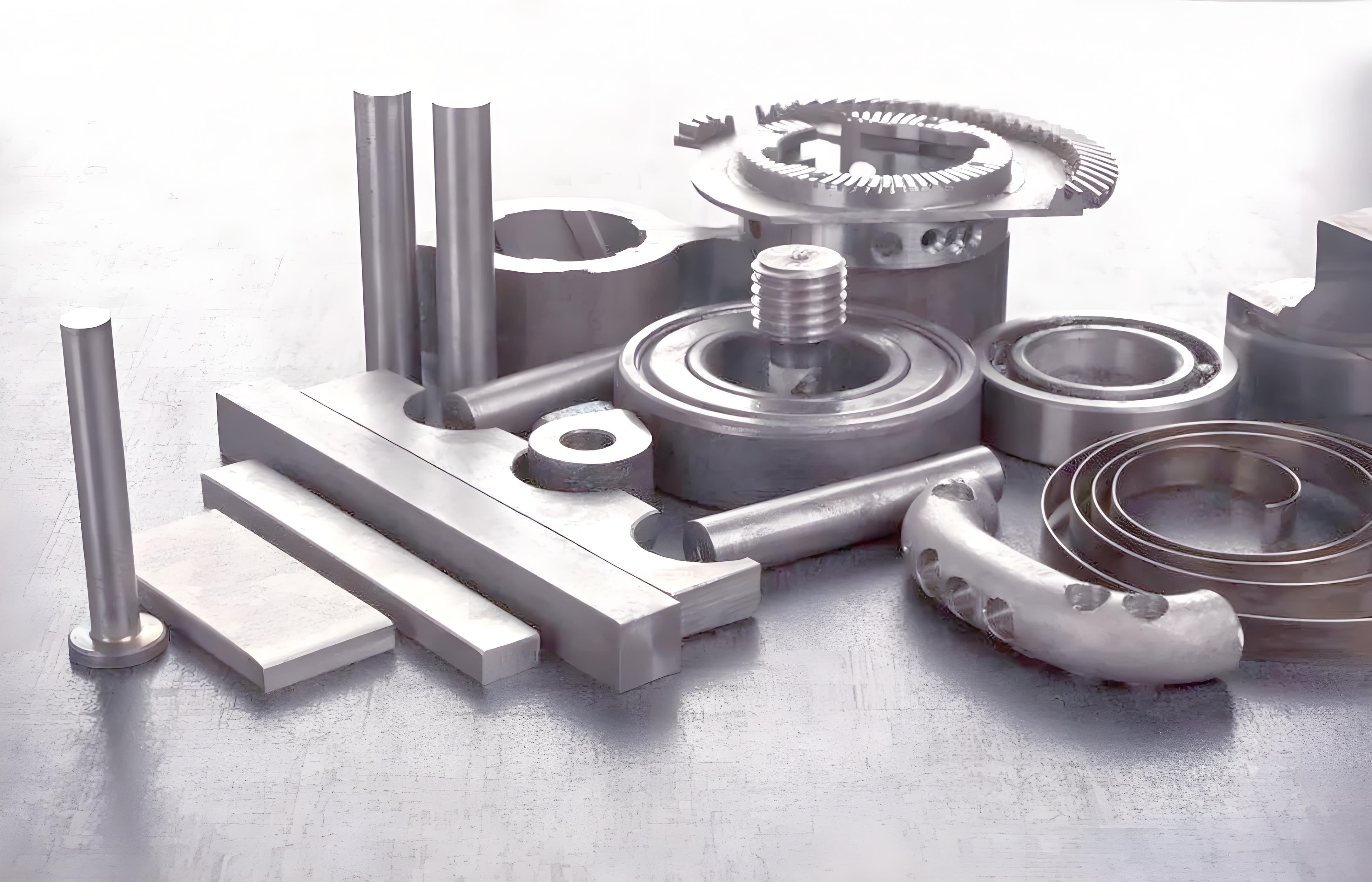

At CS Molding, we specialize in processing both titanium alloy and stainless steel for civil aerospace components . We understand the strict standards of civil aerospace—parts must be precise, compliant with global rules, and fit for their specific use.

Our team helps you pick the right material based on your component’s function, budget, and performance needs. We have the tools and expertise to machine titanium alloy’s tough surface and shape stainless steel into complex parts, ensuring every component meets your exact requirements. We focus on safety, efficiency, and reliability for all civil aerospace projects.

If you are working on a civil aerospace component and need help choosing between titanium alloy and stainless steel, or need precision processing of either material, contact us today. We will help you create parts that perform well and align with your project goals.