In aviation manufacturing, the right material directly impacts aircraft safety, fuel efficiency, and cost. Aluminum alloy has long been the workhorse material for aircraft parts due to its lightness, strength, and ease of machining. As a company specializing in precision metal forming, CS Molding has long provided aluminum alloy parts processing services to aviation clients and is familiar with the requirements for aluminum alloys across various aviation parts. Below, we’ll briefly outline the applications of aluminum alloys in key aviation parts, along with corresponding material recommendations, to help you quickly understand the core information.

I. Fuselage Parts: Load-bearing and Weight-Reducing: Choosing the Right Material is Key.

The fuselage is the “skeleton” of an aircraft, requiring it to withstand the impact of takeoff and landing while remaining as light as possible to conserve fuel. These parts require high strength and fatigue resistance from aluminum alloys, and two materials are commonly used:

1.Fuselage Skin (the thin sheet covering the exterior of the fuselage)

Recommended Material: 2024 Aluminum Alloy (aluminum-copper alloy)

Why Choose It: 2024 aluminum alloy has exceptional fatigue resistance, making it less prone to cracking when used on fuselage skins, which are subject to repeated airflow impacts over long periods of time. It is also lightweight, two-thirds lighter than steel, reducing the overall weight of the fuselage.

2. Fuselage Frame (the internal “skeleton” supporting the skin)

Recommended Material: 7075 Aluminum Alloy (aluminum-zinc alloy)

Why Choose It: 7075 is a very strong aviation aluminum alloy, with a tensile strength exceeding 600 MPa. It ensures structural stability for load-bearing parts like the fuselage frame. It also offers excellent machinability, allowing for complex frame shapes.

3.Landing Gear Connectors (Components connecting the landing gear to the fuselage).

Recommended Material: 7050 Aluminum Alloy (aluminum-zinc alloy, an upgraded version of 7075)

Why Choose It: Landing gear connectors must withstand the tremendous impact forces during takeoff and landing. 7050 offers greater stress corrosion resistance than 7075, making it less likely to break under high pressure. It also offers excellent toughness and provides impact absorption.

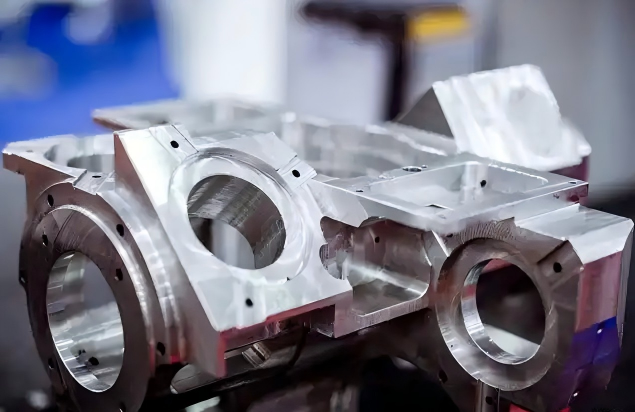

CS Molding Support: We use a combination of forging and CNC machining to produce these parts. We first forge the rough shape, then fine-mill the details to ensure the connector’s dimensional tolerance is less than 0.05mm, meeting the requirements for high-strength connections.

II. Engine Parts: Heat-Resistant and Wear-Resistant, Material Must Be “Durable”

The engine is the heart of the aircraft, and its internal components must operate in high-temperature, high-speed environments. Therefore, aluminum alloys must be heat-resistant and creep-resistant (resistant to deformation at high temperatures). The following three materials are recommended:

1.Engine Fan Blades (blades at the front of the engine, driving airflow)

Recommended Material: 6061 Aluminum Alloy (aluminum-magnesium-silicon alloy)

Why Choose It: 6061 has excellent heat resistance, capable of withstanding temperatures around 250°C, perfectly suited to the operating environment of fan blades. It is also lightweight, reducing engine resistance and saving fuel.

2.Compressor Casing (Outer Shell Enclosing the Compressor)

Recommended Material: 6063 Aluminum Alloy (aluminum-magnesium-silicon alloy, a close relative of 6061)

Why Choose It: 6063 offers superior ductility, making it easy to form complex cylindrical casings. It also offers strong corrosion resistance, resisting corrosion from the oil and gas inside the engine, and resists rusting over time.

3.Engine Fuel Line (Pipeline for Fuel Delivery)

Recommended Material: 5052 Aluminum Alloy (aluminum-magnesium alloy)

Why Choose It: 5052 offers exceptional corrosion resistance, preventing rust even from trace impurities in the fuel. It also offers excellent toughness, making it less likely to break when the pipe requires slight bending during installation.

III.Interior and Auxiliary Parts: Lightweight and Practical, Materials Must Be Easy to Process

Although interior and auxiliary parts don’t directly carry weight, they contribute to passenger comfort and the aircraft’s overall weight. Therefore, aluminum alloys must be lightweight and easy to process. The following three materials are recommended:

1.Seat Frame (Skeleton supporting the passenger seat)

Recommended Material: 3003 Aluminum Alloy (Aluminum-Manganese Alloy)

Why Choose It: 3003 is lightweight, half the weight of traditional steel frames, reducing the aircraft’s overall weight. It is also low-cost and easy to process, making it suitable for mass production of seat frames.

2.Luggage Rack (Components for storing passenger luggage)

Recommended Material: 1050 Aluminum Alloy (Pure Aluminum, 99.5% purity)

Why Choose It: 1050 has excellent ductility, allowing it to be formed into the curved outer shell of the luggage rack. It also offers easy surface treatments, such as brushing and spray-coating, for a high aesthetic appeal, meeting the aesthetic requirements of passenger aircraft interiors.

3.Door Components (Small Parts Like Door Hinges and Handles)

Recommended Material: 6082 Aluminum Alloy (Aluminum-Magnesium-Silicon Alloy)

Why Choose It: 6082 is stronger than 3003 aluminum alloy, making it less prone to deformation for hinges and handles, which are subject to constant stress. It also offers excellent machinability, allowing for complex small part shapes.

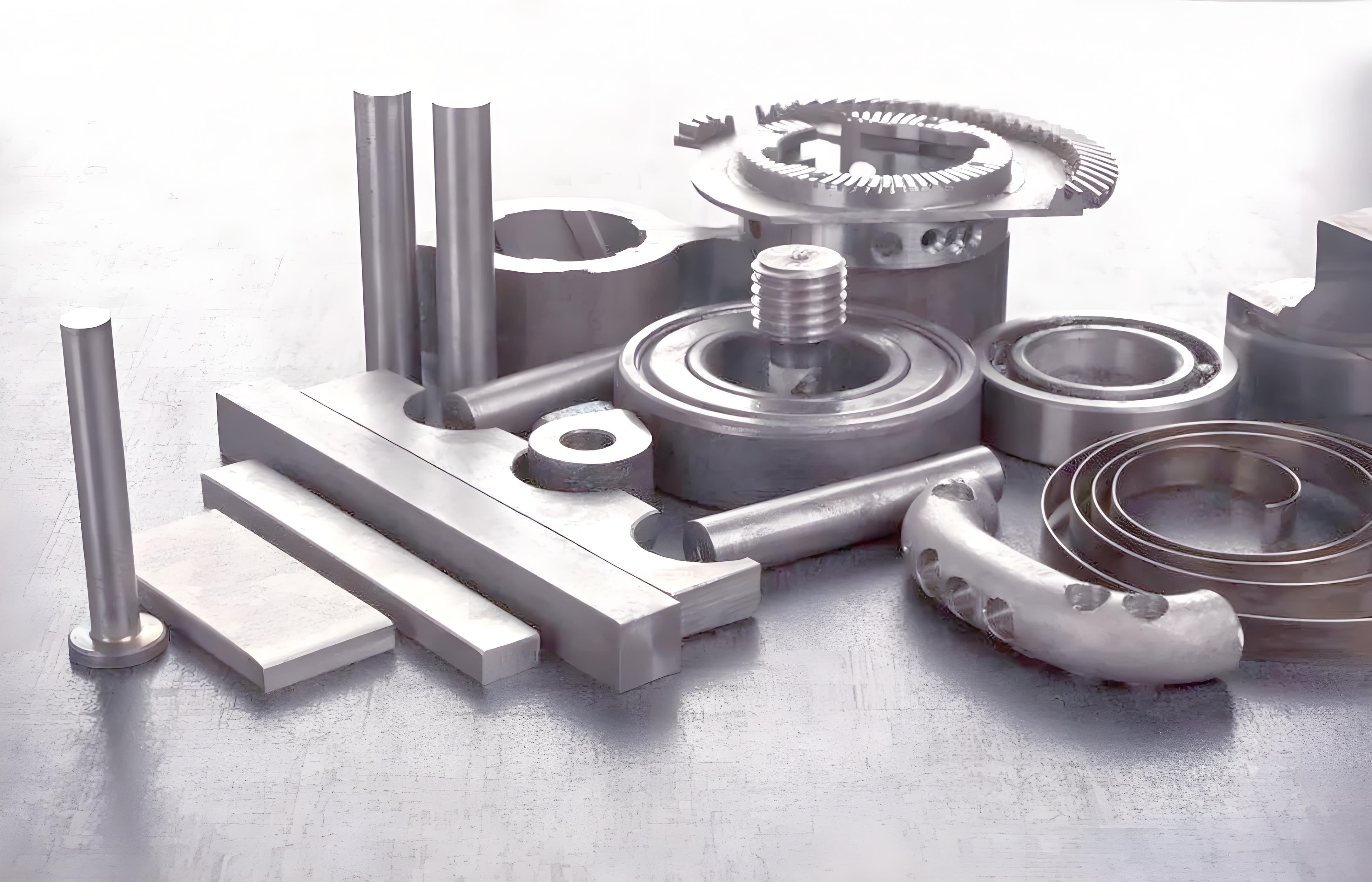

IV.Two Keys to Quality Parts

Whether it’s for the fuselage, engine, or interior parts, choosing the right aluminum alloy is only the first step. Without the right processing, even the best material is useless. CS Molding has many years of experience in aviation aluminum alloy processing and can help customers with two key tasks:

Material Recommendation: Based on the part’s intended use (e.g., fuselage skin or engine blades), we recommend the most suitable aluminum alloy grade to avoid overpriced or incorrect selections.

Custom Processing: We optimize the processing technology based on the characteristics of different aluminum alloys. For example, since 7075 aluminum alloy is prone to cracking, we use isothermal forging; if 6061 requires heat resistance, we perform a T6 heat treatment. We adhere to the aviation AS9100 quality standard, and every part is inspected to ensure compliance.

V.CS Molding Partners with You to Drive Future Development

The future aviation industry will prioritize “lightness, fuel efficiency, and environmental friendliness,” and aluminum alloys will also evolve. For example, aluminum-lithium alloys are 10%-15% lighter and stronger than current aluminum alloys. CS Molding is already in pilot production of aluminum-lithium alloy parts, enabling customers to make lighter fuselage and engine parts, contributing to greater fuel efficiency.

Aluminum alloys are widely used in aviation, with material recommendations for every part, from fuselage skins to seat frames. As a precision metal forming company, CS Molding can tailor the material selection and processing to meet part requirements, helping aviation customers create safe, lightweight, and durable aluminum alloy parts.

If your aviation project requires aluminum alloy parts, contact CS Molding today for one-stop service, from material recommendation to finished product delivery.