Aerospace manufacturing—like making commercial airplanes, civil satellites, or small private aircraft—needs materials that can handle extreme conditions. High altitudes, big temperature changes, and the need for light weight all demand a special material: titanium alloy. It’s not just strong—it’s also light, corrosion-resistant, and heat-tolerant. For civil aerospace projects, these traits make it one of the most reliable choices. At CS Molding, we work with titanium alloy to create precise parts for civil aerospace clients worldwide. Let’s break down its key uses.

I. Why Titanium Alloy Works for Civil Aerospace

1. Civil aerospace has three big needs: safety, efficiency, and long life. Titanium alloy checks all three boxes with four core strengths:

1.1 Light but strong: It’s about 40% lighter than steel, but just as strong. Lighter aircraft use less fuel; lighter satellites launch with lower cost.

1.2 Corrosion-resistant: At high altitudes, moisture, salt, and radiation can damage metals. Titanium alloy doesn’t rust or break down.

1.3 Heat-tolerant: It stays strong even at temperatures over 600°C (like near airplane engines) or as low as -250°C (in space).

1.4 Long-lasting: Titanium parts don’t wear out quickly. This cuts maintenance time and costs for airlines or satellite operators.

II.Key Civil Aerospace Applications of Titanium Alloy

Titanium alloy is used in parts that need to perform well under tough civil aerospace conditions. Here are the most common uses:

1.Commercial Airplanes (Passenger Jets)

Commercial planes carry hundreds of people, so safety and efficiency are top priorities. Titanium alloy is used in critical parts:

1.1 Fuselage (body) components: Parts like frame ribs and stringers (long, thin supports) use titanium. It’s light enough to reduce fuel use, but strong enough to hold the plane’s shape at high altitudes.

1.2 Engine parts: Jet engines get extremely hot. Titanium alloy makes turbine blades, combustion chambers, and engine casings. It resists heat and wear, so engines last longer and need fewer repairs.

1.3 Landing gear parts: Landing gear has to support the whole plane’s weight. Titanium alloy’s strength means the gear is strong but not too heavy—making takeoffs and landings safer.

1.4 Hydraulic tubes: These tubes carry fluid to control the plane’s wings and brakes. Titanium doesn’t rust, so the tubes don’t leak, even in wet or salty air (like over the ocean).

2.Civil Satellites & Spacecraft

Satellites and small civil spacecraft (like those for weather monitoring or communication) operate in space—an environment with vacuum, extreme cold, and radiation. Titanium alloy is perfect here:

2.1 Satellite structure frames: The frame holds the satellite’s sensors, batteries, and communication tools. Titanium is light (so the satellite is easier to launch) and strong (to survive the shake of a rocket launch).

2.2 Solar panel mounts: Solar panels need to stay attached to the satellite, even in space. Titanium mounts don’t corrode from radiation, so the panels keep working for years.

2.3 Propulsion system parts: Small thrusters on satellites use titanium alloy for fuel lines and nozzles. It resists the heat of fuel combustion and doesn’t react with the fuel.

2.4 Life support components (for crewed civil spacecraft): If a spacecraft carries people (like small orbital vehicles), titanium makes parts of the life support system. It’s safe for human contact and doesn’t break down in closed environments.

3.General Aviation (Small Planes & Helicopters)

General aviation includes small private planes, training aircraft, and civil helicopters (used for rescue, farming, or tourism). These vehicles need to be reliable and easy to maintain:

3.1 Helicopter rotor shafts: The rotor shaft spins the helicopter’s blades. Titanium alloy is strong enough to handle the spin and light enough to keep the helicopter agile

3.2 Small plane wing spars: The spar is the main support inside a plane’s wing. Titanium keeps the wing strong, even in turbulence, without adding extra weight.

3.3 Fuel tanks (for small aircraft): Titanium doesn’t react with fuel, so the tanks don’t rust or leak. This is key for small planes that fly in remote areas.

III.The Big Benefits for Civil Aerospace Clients

Using titanium alloy in civil aerospace projects brings clear value:

① Lower operating costs: Lighter planes use 5-10% less fuel. Longer-lasting parts mean less money spent on repairs and replacements.

② Better safety: Strong, corrosion-resistant parts reduce the risk of breakdowns—critical for passenger planes or spacecraft.

③ Easier launches (for satellites): Lighter satellite parts mean the rocket needs less fuel to reach space, cutting launch costs.

④ Longer service life: A titanium part in a plane or satellite can last 20-30 years, compared to 10-15 years for steel parts.

IV.CS Molding: Your Civil Aerospace Titanium Alloy Partner

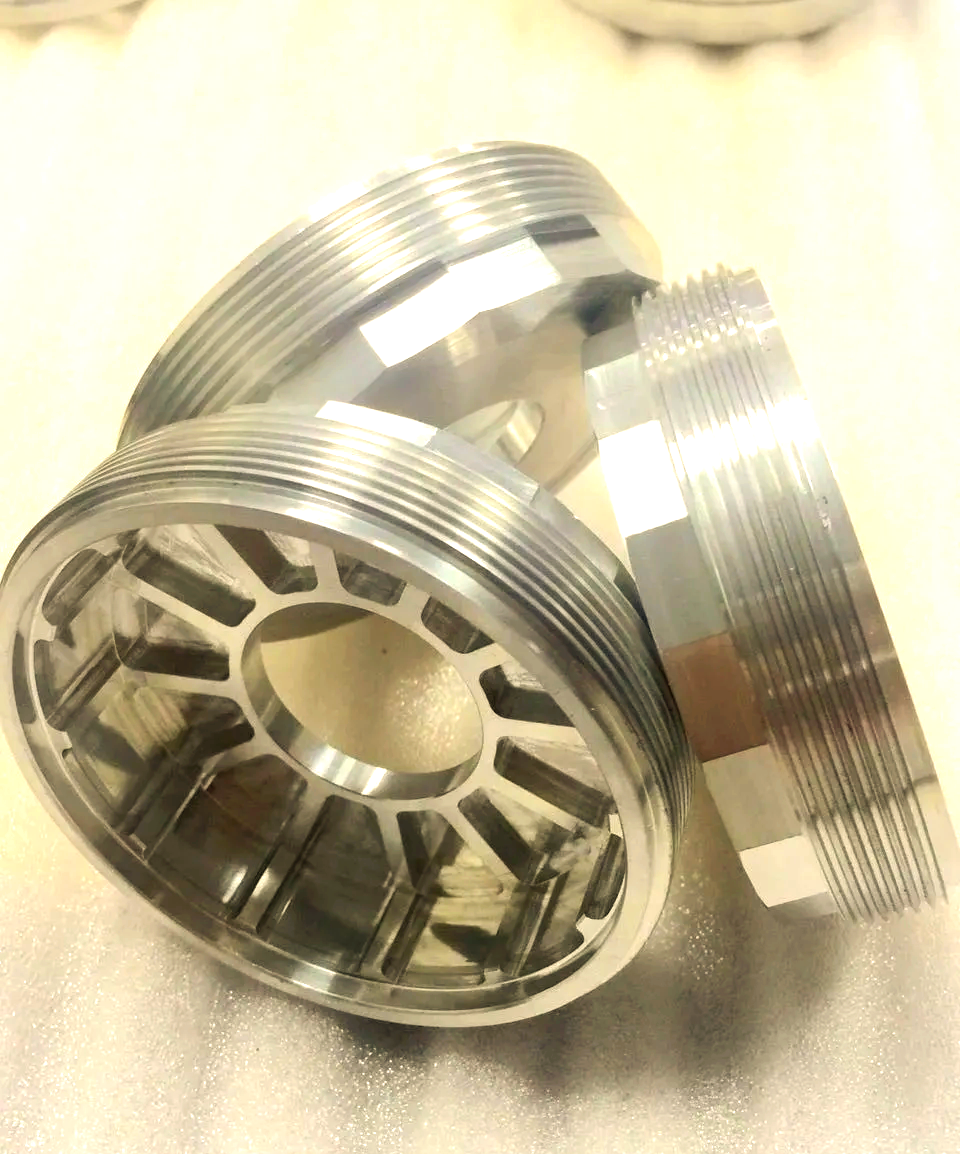

At CS Molding, we focus on creating high-precision titanium alloy parts for civil aerospace. We understand the strict standards of this industry—parts need to be exact, reliable, and meet global aerospace regulations. Whether you need airplane engine components, satellite frames, or helicopter parts, we have the expertise to make parts that fit your design and performance goals.

We work with civil aerospace clients to choose the right titanium alloy grade (there are different types for different needs) and use precise machining to get every detail right. Our goal is to help you build aerospace products that are safe, efficient, and long-lasting.

If you’re working on a civil aerospace project and need titanium alloy parts, contact us today. We’ll help you turn your ideas into parts that perform well—even in the toughest conditions.