Tool vibration is a common problem in machining. It happens when the cutting tool shakes during work. This shaking can scratch parts, ruin their smooth surface, and even make the parts unusable. For manufacturers, this means wasted time, money, and unhappy customers.

At CS Molding, we’ve worked with many clients to fix tool vibration issues. Over the years, we’ve learned simple, effective ways to stop vibration from scratching parts. Let’s break them down—no complex words, just easy steps you can follow.

I. Choose the Right Tool (Don’t Use Too Long or Too Thin Tools)

The first step to stop vibration is picking the right cutting tool. Many scratches happen because the tool is too long or too thin.

Why this causes vibration:

Long or thin tools bend easily when cutting. When they bend, they shake. This shake rubs the tool against the part, leaving scratches.

What to do:

Pick a tool that’s as short as possible for your job. For example, if you need to cut a small hole, use a short drill bit—not a long one.

Choose a tool with a thick diameter. Thick tools are stronger and don’t bend as much.

Check if the tool is sharp. Dull tools need more force to cut, which makes them vibrate more. Replace dull tools early.

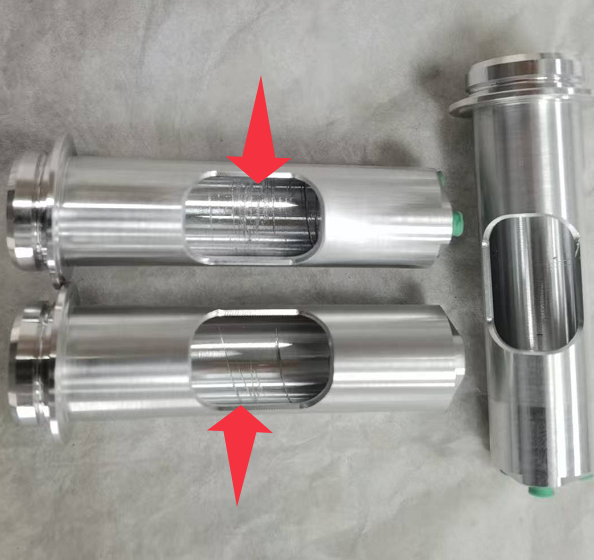

II.Clamp the Tool Tightly (Don’t Let It Loosen)

Even a good tool will vibrate if it’s not clamped tightly in the machine. A loose tool moves around while cutting, which scratches the part.

Why this causes vibration:

The machine holds the tool with a “chuck” (a small clamp). If the chuck is loose, the tool spins unevenly and shakes. This shake leads to scratches.

What to do:

Clean the chuck and the tool before clamping. Dust or metal bits can stop the tool from sitting tight.

Tighten the chuck properly. Use the right tool (like a wrench) to make it snug—don’t just hand-tighten.

Check the chuck regularly. Over time, chucks wear out. If yours feels loose, replace it.

III..Secure the Part Firmly (Don’t Let It Move)

Vibration doesn’t just come from the tool—it can also come from a loose part. If the part moves while being cut, the tool will scratch it.

Why this causes vibration:

The machine holds the part with a “fixture” (a device like a clamp or vacuum). A loose fixture lets the part shift. When the part shifts, the tool cuts unevenly and shakes.

What to do:

Use the right fixture for your part. For small parts, use a vice (a strong clamp). For thin parts (like aluminum sheets), use a vacuum fixture (it suctions the part to the machine).

Make sure the part sits flat. If the part is tilted, it will move during cutting.

Add extra support for thin parts. Thin parts bend easily—use small blocks to hold them up.

IV. Adjust Machining Speed and Feed Rate

The speed of the tool (how fast it spins) and the feed rate (how fast it moves over the part) can cause vibration if they’re wrong.

Why this causes vibration:

If the tool spins too fast, it creates a “whirring” shake.

Once the feed rate is too high, the tool pushes too hard on the part, making it vibrate.

If either is too low, the tool rubs the part instead of cutting it—this also scratches.

What to do:

Start with slow speeds. Test the tool at a low speed first. If there’s no vibration, you can speed up a little.

Adjust the feed rate. A good rule: if the tool sounds loud or shakes, slow down the feed rate.

Use “test cuts” on scrap material. Don’t cut your real part first—test on a piece of the same material to find the best speed.

V. Maintain Your Machine Regularly

Old or poorly maintained machines cause more vibration. A machine with loose parts or a worn-out spindle (the part that spins the tool) will make the tool shake.

Why this causes vibration:

Loose machine parts (like screws or belts) shake when the machine runs. This shake transfers to the tool.

A worn spindle can’t spin the tool evenly. An uneven spin leads to vibration and scratches.

What to do:

Tighten loose screws and belts every month.

Lubricate the spindle (add oil) as the machine’s manual says. This keeps it spinning smoothly.

Have a professional check the machine once a year. They can fix hidden issues you might miss.

VI. CS Molding: We Help You Avoid Scratches

At CS Molding, we know that even small scratches can ruin a part. That’s why we use these steps every day to keep our clients’ parts smooth and perfect. Whether you’re machining aluminum, plastic, or brass, we work with you to find the right tools, fixtures, and speeds for your job.

If you’re tired of tool vibration scratching your parts, contact CS Molding today. Our team will help you fix the problem—and make your machining process smoother.