Precision manufacturing has long been a hallmark of innovation and advancement in various industries. Among the myriad technologies available, CNC machining stands out as a leading choice for achieving unparalleled accuracy and precision. In this article, we will explore the world of custom CNC machining, its evolution, types, and advantages, and then introduce you to CS Molding’s expertise in this field.

The Evolution of CNC Machining

The technology of CNC (Computer Numerical Control) has revolutionized manufacturing processes across industries. At its core, CNC machining involves the use of computer programs to control and automate the operation of machining tools and equipment. This precise control allows for manufacturing complex and intricate parts and components with unmatched accuracy. Custom CNC machining takes this a step further, where raw material is transformed into a custom-designed part or product using CNC machines.

The rich history of CNC machining dates back to the 1940s. CNC machines use punched tape, functioning to store telecommunications and data. But later, it was replaced by analog computing technologies. In the 1960s to 1970s, digital technologies emerged, which achieved automated production and more productive processes.

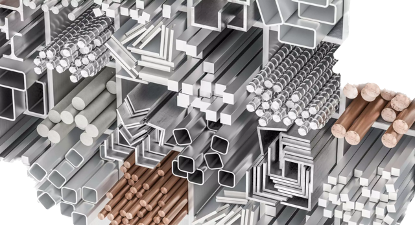

Today, CNC processing relies on highly automated motion control systems based on the foundational components of command functions, drive/motion systems, and feedback mechanisms. Modern CNC machines are electronically controlled, ensuring predictability and the ability to work with various materials, from metal to wood and plastics, as well as delivering custom CNC machining products.

Similarities and Differences in the Types of Custom CNC Machining

Custom CNC machining encompasses various processes, but two of the most common methods are CNC milling and CNC turning. Let’s explore their similarities and differences:

Similarities

Computer Control: Both CNC milling and CNC turning are controlled by computer programs, ensuring precise and consistent results.

Precision: Both methods offer exceptional precision, allowing the manufacturing of intricate and complex parts with tight tolerances.

Differences

1. Operation Orientation: CNC milling involves cutting into a workpiece from various angles, making it suitable for creating 2D and 3D shapes. In contrast, CNC turning rotates a workpiece against a cutting tool, primarily used for cylindrical parts like shafts and bushings.

2. Tool Features: Milling uses rotary cutting tools while turning employs single-point cutting tools, each suited to its specific purpose.

3. Cut: Milling removes material from a workpiece’s surface while turning creates cylindrical shapes by removing material from a rotating workpiece.

Advantages of Custom CNC Machining

Custom CNC machining offers several advantages that make it a preferred choice for precision manufacturing:

Precision and Accuracy

Custom CNC machining delivers unrivaled precision and accuracy, ensuring that every part or component meets exact specifications, and reducing errors and waste.

Flexibility

The versatility of CNC machines allows for the production of a wide range of parts, from simple to highly complex, without the need for costly tooling changes.

Efficiency and Cost-Effectiveness

CNC machining is efficient, reducing production times and costs associated with manual machining. Additionally, it minimizes material wastage, making it an environmentally friendly option.

Introducing CS Molding Custom CNC Machining

For those seeking high-quality custom CNC machining services, we, CS Mold, are a reliable and experienced partner. Here are our advantages:

DFM Analysis

At CS Mold, we understand that every project is unique. Upon receiving your inquiry, our team initiates a thorough Design for Manufacturability (DFM) analysis. This preliminary report helps identify potential issues and optimizations early in the process, ensuring that your project is executed efficiently and cost-effectively.

High-Quality Standards

Quality is at the core of what we do. CS Mold is ISO 9001 and IATF 16949 certified, guaranteeing that our machining processes meet rigorous international standards. We take quality seriously, and our team inspects every step of the CNC machining process to ensure precision, consistency, and reliability in the final product.

No Minimum Order Quantity (MOQ)

Compared with other CNC machining providers, CS Mold doesn’t impose a minimum order quantity. We understand that your needs may vary, and we are committed to accommodating both small and large-scale projects with the same level of dedication and professionalism.

Custom Surface Treatments

CS Mold offers a wide range of custom surface treatment options to enhance the functionality and aesthetics of your CNC-machined parts. Whether you require plating, passivation, powder coating, screen printing, or heat treating, we have the expertise and capabilities to deliver the surface finish your project demands.

Conclusion

Custom CNC machining is the leading technology in precision manufacturing, offering a world of possibilities for industries across the board. As CNC Machining technology continues to evolve, the demand for custom CNC machining services is set to increase. Whether you require intricate prototypes or high-volume production, the advantages of CNC machining, such as precision, flexibility, and cost-effectiveness, make it the ideal choice.

When it comes to custom CNC machining, we, CS Mold, stand out as a trusted CNC machining company with a track record of excellence. Our expertise, equipment, and commitment to quality make us on the top list for those seeking precision and reliability in their manufacturing processes. Choose CS Mold and experience the future of precision manufacturing today. If you have any doubts about CNC machining and are interested in our service, please contact us!