Machining is how we make precise metal or plastic parts. Two common methods are 5-axis machining and conventional machining (like 3-axis). Conventional machining works for simple parts, but 5-axis machining is better for complex, high-precision jobs. At CS Molding, we use both—but we often recommend 5-axis for clients who need better quality or faster production. Let’s break down the key advantages of 5-axis machining and where it works best—simple words, no jargon.

I.First: What’s the Difference?

Conventional machining (3-axis): The tool moves in 3 directions (up/down, left/right, forward/backward). It’s like drawing on paper with a pen that only moves in straight lines.

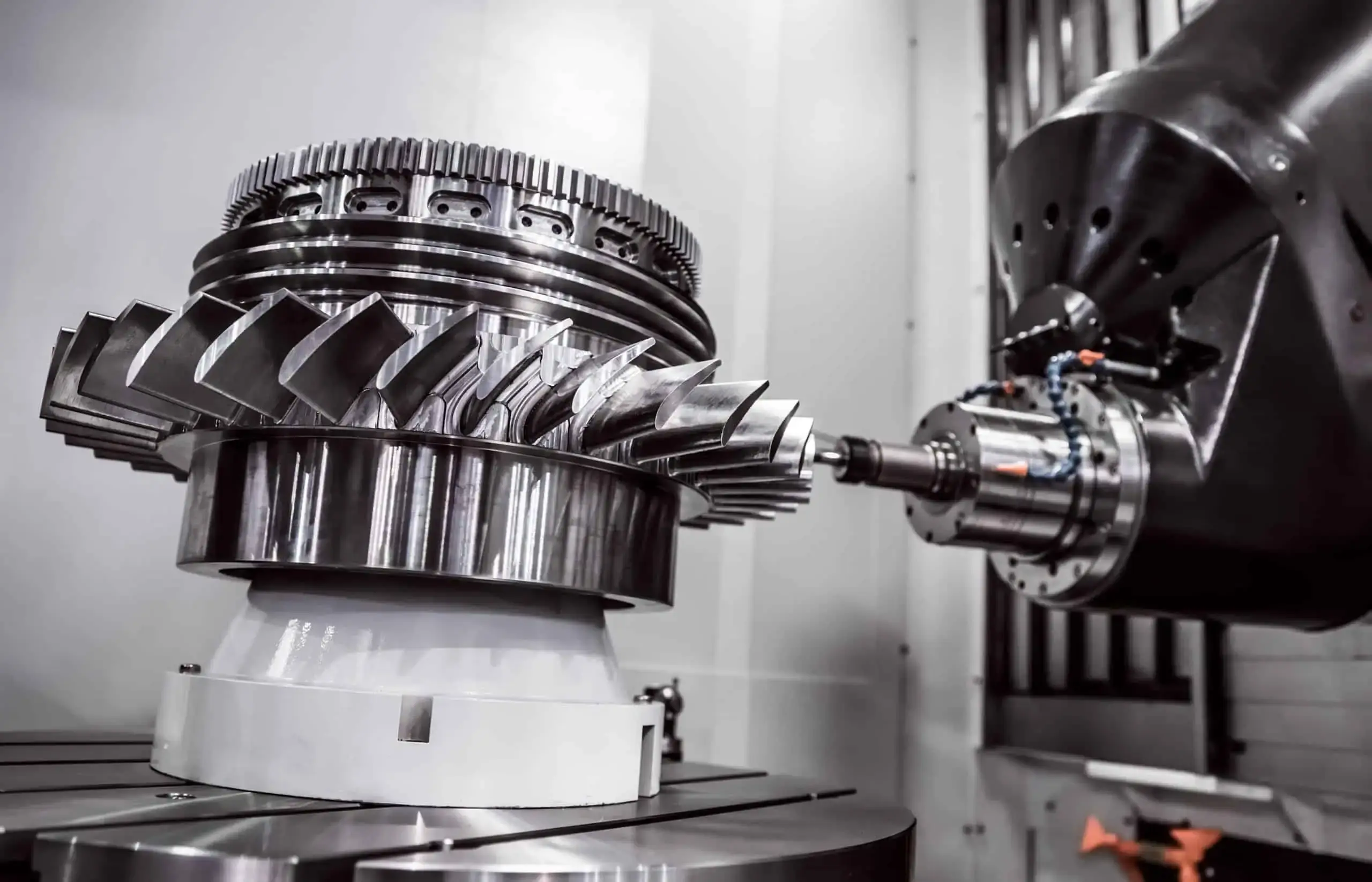

5-axis machining: The tool moves in 5 directions. It adds two more rotations (twisting left/right, tilting up/down). It’s like a hand that can turn and angle the pen—reaching every spot easily.

This extra movement makes 5-axis machining more flexible. Now let’s look at its biggest advantages over conventional machining.

1. Better Precision (Fewer Mistakes)

Precision means parts are exactly the right size and shape. Conventional machining can’t always reach all angles, leading to small errors. 5-axis fixes this.

1.1 Why 5-axis is better:

– The tool can approach the part from any angle. No more “blind spots” where the tool can’t reach.

– You don’t need to move the part multiple times (more moves = more chances for error). 5-axis does the job in one go.

1.2 Conventional machining’s limit:

A complex part (like a curved metal bracket) might need 3-4 repositionings with 3-axis. Each move shifts the part slightly—errors add up over time.

2. Faster Production (Saves Time)

Time is money in manufacturing. 5-axis machining cuts production time by reducing steps.

2.1 Why 5-axis is better:

– One setup = one finished part. Conventional machining needs multiple setups (moving the part, changing tools). 5-axis does everything at once.

– Faster tool paths. The tool moves smoothly around complex shapes—no stopping to reposition or adjust.

2.2 Conventional machining’s limit:

A part with multiple angles might take 4 hours with 3-axis (including setup time). 5-axis can make the same part in half the time or less.

3. Can Make Complex Shapes (Impossible for Conventional)

Many modern products need complex parts—curves, angles, or hollowed-out sections. Conventional machining can’t handle these well.

3.1 Why 5-axis is better:

– The tool tilts and rotates to follow curved surfaces. It’s like carving a statue with a tool that can reach every contour.

– No need for custom fixtures (special clamps) to hold the part. 5-axis adjusts to the part’s shape naturally.

3.2 Conventional machining’s limit:

A part like a spiral gear or a curved plastic housing would need expensive custom tools with 3-axis. Even then, the finish is often rough or uneven.

4. Less Material Waste (Saves Money)

4.1 Why 5-axis is better:

– The tool cuts closer to the final shape. Conventional machining leaves more extra material (which gets thrown away).

– Fewer errors mean fewer scrapped parts. 3-axis often makes 5-10% wasted parts—5-axis cuts that to 1-2%.

4.2 Conventional machining’s limit:

A large aluminum part might lose 20% of its weight to waste with 3-axis. 5-axis reduces waste to 5% or less.

5. Better Surface Finish (Smoother Parts)

5.1 Why 5-axis is better:

– The tool moves in a continuous, smooth path. Conventional machining’s tool path is choppy (like drawing a curve with short straight lines).

– No tool marks from repositioning. 3-axis leaves lines where the tool stopped and started.

5.2 Conventional machining’s limit:

A plastic housing for electronics might need 1 hour of polishing after 3-axis machining. 5-axis makes it smooth enough without extra work.

II.Key Applications: When to Choose 5-Axis Machining

5-axis machining isn’t for every job—but it’s perfect for these industries:

– Aerospace: Curved brackets, engine parts (need high precision and strength).

– Medical Devices: Tiny angled parts (like surgical tools) or custom implants.

– Automotive: Complex gears, curved interior parts, or performance parts.

– Electronics: Smooth casings, small connectors, or custom heat sinks.

– Toys: Intricate gears, curved toy parts, or custom-shaped shells.

Conventional machining is still good for simple parts (like flat brackets or basic blocks)—it’s cheaper and faster for straightforward jobs. At CS Molding, we help you pick the right method for your part.

III.CS Molding: Your 5-Axis Machining Partner

At CS Molding, we have 5-axis machining equipment that handles metal, plastic, and composite parts. We don’t just use the technology—we know how to get the most out of it. Whether you need complex aerospace parts or smooth toy casings, we’ll advise if 5-axis is the right fit for your project.

We focus on balancing quality, speed, and cost. If you’re making complex, high-precision parts—or if you’re tired of wasted material, slow production, or rough finishes—5-axis machining is the solution. Contact CS Molding today. We’ll help you get better parts, faster and for less money.