At CS Mold, our commitment to perfection extends beyond mere pride; it’s ingrained in our DNA. We take pride in our meticulous approach to compression molding, a process that seamlessly blends cutting-edge technology with precision engineering. We navigate the intricate world of compression molding with a meticulous approach that marries cutting-edge technology and precision engineering. Let’s delve deeper into the artistry and innovation what is compression molding process by CS Mold.

Precision Mold Manufacturing: Where Art Meets CNC Technology

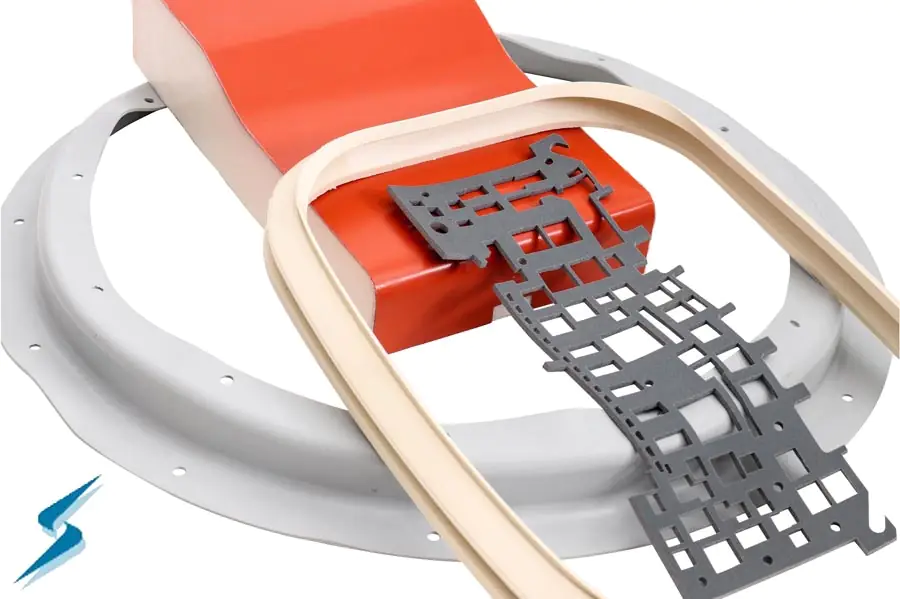

Our journey begins with the meticulous manufacturing of compression molds. Employing CNC machining and polishing techniques, we craft molds with unparalleled precision. For straightforward silicone part designs, a two-plate mold is the go-to solution. This mold comprises the cavity side and core side, ensuring a seamless and efficient molding process. Once crafted, the mold template is assembled with utmost precision, ready to embark on its transformative journey within our compression molding machines.

Loading the Canvas: Silicone Materials and Precision Parameters

The heart of our compression molding process lies in the careful selection of silicone materials, such as HCR (High Consistency Rubber) or LSR (Liquid Silicone Rubber). These materials are not just loaded into the template; they are strategically placed to ensure optimal results. The compressor takes charge, setting the perfect combination of heat, pressure, and time. This orchestration allows the silicone material to gracefully spread throughout the entire mold cavity, embracing its form and curing to perfection.

Unveiling Excellence: The Culmination of Precision

As the press releases its grip, a moment of anticipation unfolds. The template gracefully separates, revealing the masterpiece within – the cured silicone component. With finesse and accuracy, the silicone part is gently removed, marking the completion of a normal compression molding cycle for simple silicone parts. This culmination of precision ensures that each component meets the stringent quality standards set by CS Mold.

Conclusion

Choosing CS Mold as your compression molding partner is choosing excellence at every stage. Our commitment to precision, from mold manufacturing to the final component extraction, sets us apart in the industry. Collaborate with us to experience the seamless integration of technology and craftsmanship in the creation of your silicone components. Are you ready to elevate your projects with precision-engineered silicone components? Connect with CS Mold today. Fill out the form on our website to initiate the conversation. For specific inquiries and immediate assistance, reach out to our dedicated team. Let’s shape perfection together – the CS Mold way.