How does injection molding work? As a premier provider of injection molding services, CS Mold is dedicated to delivering high-quality plastic parts to businesses across various industries. In this article, we will provide a comprehensive guide on how injection molding works, highlighting the key steps involved in the process. Discover the power of injection molding and how CS Mold can be your trusted partner in bringing your plastic product ideas to life.

Mold Setup and Material Feeding

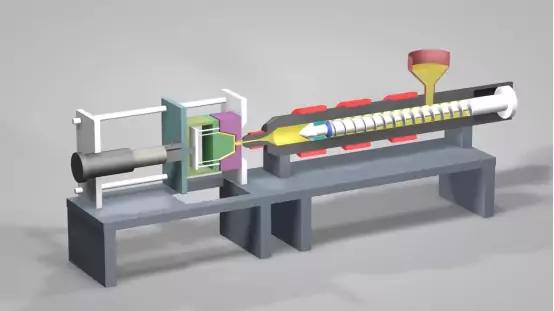

The injection molding process begins with the preparation of the mold. At CS Mold, we meticulously mount the mold onto our advanced injection molding machines. Next, thermoplastic material in the form of pellets or granules is fed into the machine’s hopper. We carefully select the appropriate material based on your requirements to ensure optimal performance and durability of the final product.

Injection, Holding, and Cooling

The heart of the injection molding process lies in the injection stage. The molten plastic material is injected into the mold cavity under high pressure using a screw or plunger. CS Mold’s skilled technicians closely monitor and control the injection parameters, including temperature, speed, and pressure, to achieve precise and consistent results.

After injection, the molten plastic is held under pressure for a specific time to ensure complete filling and to allow for proper cooling and solidification. Cooling channels integrated within the mold help expedite the cooling process, ensuring efficient production cycles.

Ejecting and Finishing

Once the plastic has cooled and solidified, the mold is opened, and the finished part is ejected from the mold. CS Mold employs advanced ejector pin systems or robotic mechanisms to safely and efficiently remove the parts from the mold. To guarantee the highest quality, our team conducts rigorous inspections and testing, including dimensional checks, visual inspections, and functional assessments.

Conclusion: Unlocking the Potential of Injection Molding with CS Mold

Now that you have a comprehensive understanding of how injection molding works, it’s time to harness its power for your business. CS Mold, with our expertise, advanced facilities, and commitment to quality, is here to assist you at every step of the way.

To get started on your injection molding project, simply fill out our online form or send us an email. Our dedicated team is eager to discuss your requirements, provide personalized solutions, and deliver outstanding results.

Partner with CS Mold and experience the difference. Send us a message now and discover how we can bring your plastic product ideas to life with our superior injection molding services.

Read Also:

https://www.csmolding.com/companies/streamlining-rapid-tooling-systems-at-cs-mold/

https://www.csmolding.com/companies/mastering-rubber-compression-molding-at-cs-mold/