In the dynamic landscape of manufacturing, CS Mold provides a strategic perspective on the critical choice between rapid tooling vs. conventional tooling. As we delve into this comparative analysis, CS Mold’s commitment to innovation and efficiency shines through.

A Comparative Analysis: Rapid Tooling vs. Conventional Tooling

Manufacturing tooling is traditionally fraught with complexities and time investments. Conventional processes, such as machining, casting, or injection molding, demand significant time and cost investments. CS Mold recognizes these challenges and offers a transformative alternative with rapid tooling.

CS Mold leverages rapid tooling, incorporating advanced techniques like 3D printing, CNC machining, and vacuum casting. This approach brings a more flexible and resource-efficient solution to the table. The streamlined processes in rapid tooling enable quicker fabrication of tooling components, making it suitable for prototyping, low-volume production, and bridge tooling. CS Mold’s strategic use of cutting-edge technologies positions rapid tooling as a compelling choice for businesses seeking efficiency without compromising quality.

CS Mold’s Shared Mold Base System: Lowering Tooling Costs for On-Demand Production

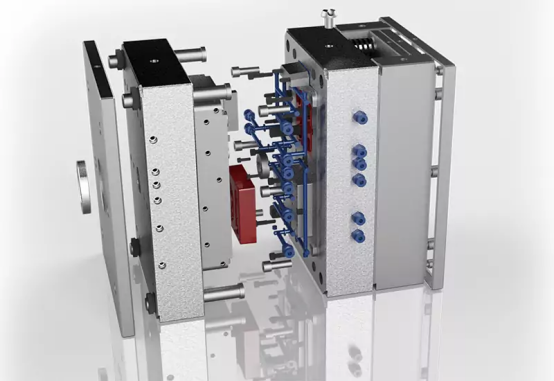

CS Mold takes innovation to new heights by implementing a shared mold base system in rapid tooling. This strategic approach goes beyond traditional boundaries and delivers remarkable benefits, particularly in lowering tooling costs. For businesses involved in on-demand production and low-volume manufacturing, this cost reduction factor is pivotal. By utilizing a shared mold base system, CS Mold optimizes resource utilization, eliminates duplication, and drives down tooling expenses. This innovative approach enhances cost-effectiveness without compromising quality or lead times. With our commitment to pushing boundaries and finding creative solutions, CS Mold empowers businesses to achieve their production goals while maintaining a competitive edge in the marketplace.

By utilizing a shared mold base system, CS Mold maximizes cost efficiency without compromising on quality. This approach allows for the rapid production of tooling components, making it especially suitable for businesses that require quick iterations, smaller production runs, or prototypes. CS Mold’s commitment to delivering cost-effective solutions through the shared mold base system showcases our dedication to providing strategic advantages to our clients.

Conclusion

In summary, CS Mold’s strategic advantage in the realm of rapid tooling vs. conventional tooling lies in our commitment to innovation and efficiency. The comparative analysis emphasizes the transformative potential of rapid tooling, backed by CS Mold’s expertise in leveraging cutting-edge technologies. With a shared mold base system, CS Mold not only lowers tooling costs but also accelerates the production timeline, making rapid tooling an ideal choice for businesses seeking strategic advantages in the competitive manufacturing landscape.