What are three advantages of compression molding? Discover the three advantages of compression molding, including minimal material loss, suitability for large-scale production, and the expertise of CS Mold. With a focus on efficiency and sustainability, CS Mold maximizes the potential of compression molding to deliver high-quality components while minimizing waste. Choose CS Mold as your partner to unlock the power of compression molding for your business’s size and thickness needs.

Maximizing Efficiency with Minimal Material Loss

Curious what are three advantages of compression molding? CS Mold is proud to uncover these benefits, and one of our key strengths is the minimal loss of raw materials. This advantage serves as a cornerstone of our commitment to efficient and sustainable manufacturing practices. So, what are the other two advantages of compression molding that we offer?

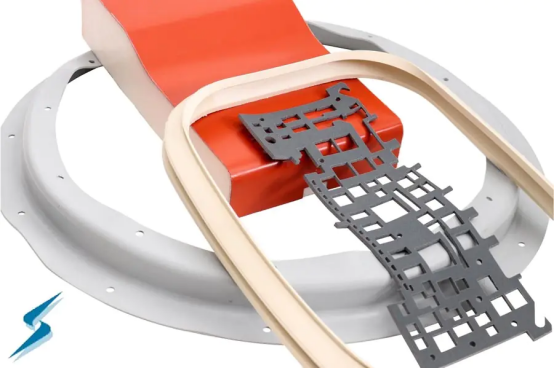

In the realm of silicone compression molding, the process is meticulously designed to minimize raw material waste. By emphasizing precision in every step, from CNC machining to the actual compression molding, CS Mold ensures that the amount of material used aligns precisely with the requirements of the final product. This not only contributes to cost-effectiveness but also reflects our dedication to environmentally conscious manufacturing.

Our approach at CS Mold is not just about creating components; it’s about doing so in a way that maximizes efficiency while minimizing the ecological footprint. The minimal material loss in silicone compression molding is not just an advantage; it’s a testament to our commitment to providing sustainable solutions for businesses looking to make an impact without compromising on quality.

Empowering Large-Scale Production: The Sweet Spot of Compression Molding

As we delve deeper into the advantages of compression molding, the second strength becomes apparent: its suitability for producing large items and thicker parts. At CS Mold, we recognize the pivotal role this plays in empowering businesses engaged in large-scale production.

Compression molding’s ability to efficiently create sizable components without compromising quality positions it as the ideal solution for industries where size and thickness matter. Our expertise at CS Mold lies in leveraging this advantage to its fullest potential. By understanding the intricacies of compression molding and tailoring our processes to meet the demands of large-scale production, we enable businesses to navigate the complexities of size and thickness seamlessly.

CS Mold’s commitment to excellence extends beyond the manufacturing floor. We are not just providers of compression molding services; we are partners dedicated to delivering innovative solutions that align with the unique needs of our clients. Our expertise ensures that the advantages of compression molding, particularly in producing large items and thicker parts, are harnessed for optimal results.

Conclusion

In short, wondering what are three advantages of compression molding? CS Mold offers three key benefits: minimal material loss, the ability to facilitate large-scale production, and a commitment to efficiency, sustainability, and excellence. Choose CS Mold as your trusted partner to leverage these advantages and drive your business towards success in size and thickness.