Welcome to CS Mold, your leading provider of sheet metal fabrication services. With our expertise and dedication to excellence, we are here to support your sheet metal projects from start to finish. In this article, we will explore the world of sheet metal projects and demonstrate how CS Mold can help you achieve outstanding results.

Unleashing the Potential of Sheet Metal Projects

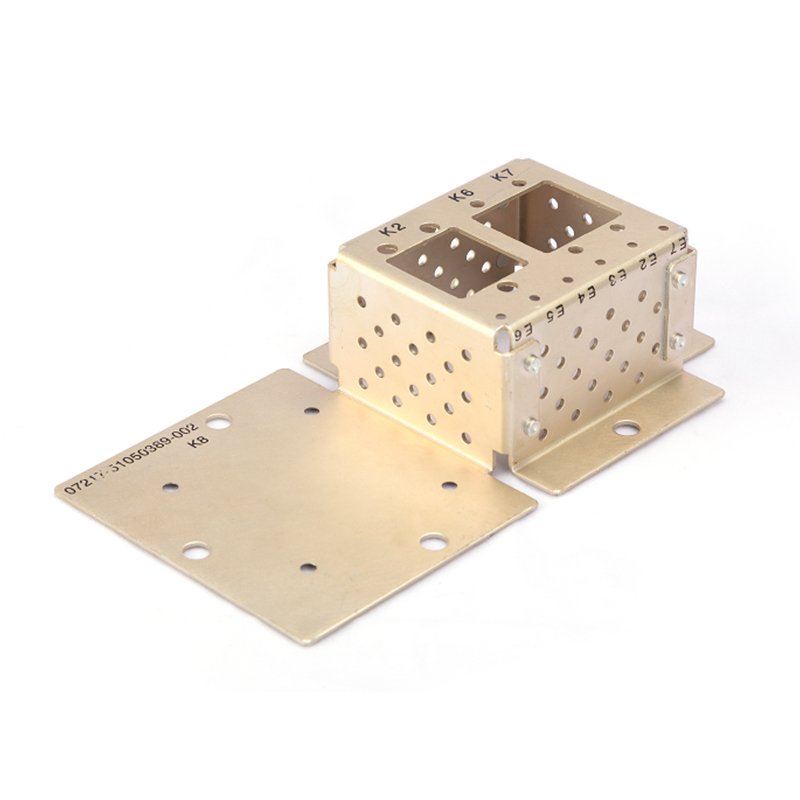

Sheet metal projects offer immense possibilities across various industries. From electrical enclosures to computer parts, casings, brackets, cabinets, and mounting plates, sheet metal is a versatile material that can be shaped and manipulated to suit your specific requirements. At CS Mold, we understand the unique demands of sheet metal projects and have the expertise to bring your ideas to life. With our state-of-the-art facilities and skilled team, we ensure the highest quality and precision in every project we undertake.

Customized Solutions for Your Sheet Metal Needs

The first step in the sheet metal fabrication process is the design phase. Our team of experienced engineers and designers collaborates with you to understand your project requirements and create detailed designs that optimize functionality, manufacturability, and cost-effectiveness. We utilize advanced design software and techniques to create accurate 3D models and simulations, allowing you to visualize the final product before production begins. Our expertise in design ensures that your sheet metal project is tailored to your specific needs and objectives.

Material selection is another crucial aspect of sheet metal fabrication. We work closely with you to determine the ideal material for your project, considering factors such as strength, durability, corrosion resistance, and cost. With a wide range of sheet metal materials available, including stainless steel, aluminum, and carbon steel, we can recommend the most suitable option to meet your requirements.

Meticulous Fabrication Process for Outstanding Results

Once the design and material selection are finalized, we move on to the fabrication phase. Cutting is the initial step, where we use advanced cutting techniques such as laser cutting or waterjet cutting to precisely shape the sheet metal according to the design specifications. This ensures accuracy and minimizes material waste.

Forming and bending follow the cutting process. We utilize a variety of techniques, including press brakes and roll forming machines, to shape the sheet metal into the desired forms and angles. Our skilled technicians carefully manipulate the metal to achieve precise bends and curves, ensuring the dimensional accuracy of the final product.

Joining and assembly are vital steps in sheet metal fabrication. We utilize various techniques such as welding, riveting, and fastening to securely join the different components together. Our experienced technicians are skilled in these techniques, ensuring strong and durable connections that meet your project requirements.

Finishing is the final step in the sheet metal fabrication process. We offer a range of finishing options, including powder coating, painting, and plating, to enhance the aesthetics and provide additional protection to the sheet metal components. This ensures a professional and polished appearance for your finished product.

Conclusion

CS Mold is your trusted partner for successful sheet metal projects. Our expertise, state-of-the-art facilities, and commitment to customer satisfaction make us the ideal choice for all your sheet metal fabrication needs. From design and material selection to cutting, forming, joining, and finishing, we follow a meticulous process to ensure outstanding results. Contact us today by filling out the contact form on our website or send us an email to discuss your sheet metal project and experience the excellence of CS Mold.