When it comes to precision manufacturing of plastic products, custom injection molding stands out as the preferred method for producing high-quality, consistent parts. At CS Mold, we specialize in offering top-notch custom injection molding services that cater to a wide range of industries and applications. In this article, we’ll walk you through the process of injection molding and explain how CS Mold can be your trusted partner in this versatile manufacturing technique.

The Process of Injection Molding

- Mold Setup

The first step in the injection molding process involves setting up the mold. The mold is carefully prepared and mounted onto the injection molding machine. At CS Mold, we have a state-of-the-art facility equipped with advanced machinery and experienced technicians who ensure precise mold setup for each project.

- Material Feeding and Melting

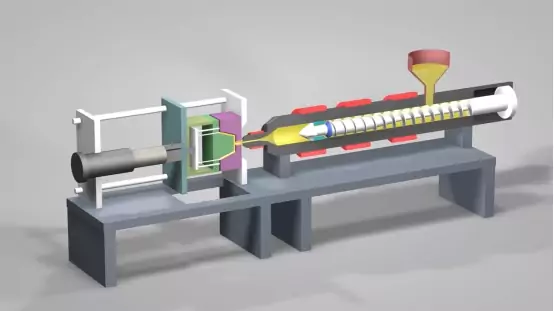

Thermoplastic material, usually in the form of pellets or granules, is fed into the machine’s hopper. Our team at CS Mold has extensive experience in working with various thermoplastic materials, ensuring that we select the right one for your specific application.

- Injection

Once the material is in the hopper, it is fed into the machine’s barrel, where it is heated to a molten state. The molten plastic is then injected into the mold cavity under high pressure. This is where precision and expertise come into play, and CS Mold excels in achieving accurate injection results.

- Holding and Cooling

After the molten plastic is injected into the mold cavity, it is held under pressure for a specific time to ensure complete filling and to allow for proper cooling and solidification. The design of the mold, including cooling channels, helps expedite this process while maintaining quality.

- Ejecting and Finishing

Once the plastic has cooled and solidified within the mold, it’s time to retrieve the finished part. The mold is opened, and the part is ejected using ejector pins or a robotic system. CS Mold’s meticulous approach ensures that each part is finished to the highest standards.

The CS Mold Advantage

At CS Mold, we take pride in offering a wide range of advantages to our clients:

Expertise: With years of experience in custom injection molding, our team possesses the knowledge and skills needed to meet your specific requirements.

Advanced Equipment: Our state-of-the-art machinery, including machines with single or multiple cavities, enables us to efficiently produce a wide variety of parts.

Efficiency: The injection molding process is known for its efficiency and speed, allowing us to meet tight deadlines and deliver consistent results.

Custom Solutions: CS Mold understands that every project is unique. We work closely with our clients to provide customized injection molding solutions tailored to their needs.

Conclusion

if you’re in search of a reliable partner for your custom injection molding needs, CS Mold is your go-to choice. Our commitment to precision, efficiency, and customized solutions sets us apart in the industry. With our expertise, advanced equipment, and dedication to quality, we’re ready to bring your plastic product ideas to life. Don’t hesitate to reach out and explore the possibilities with CS Mold. Contact us today by filling out our contact form or sending us an email, and let’s embark on a journey of turning your visions into reality through custom injection molding. Your success is our mission!