In the vibrant realm of manufacturing, where imagination reigns supreme, CS Mold stands as a beacon of innovation, weaving together the realms of possibility and precision through the art of rapid prototyping 3D printing. With an unwavering dedication to excellence and a commitment to redefining the boundaries of what’s achievable, we embark on a journey that transcends mere creation, delving into the very essence of what it means to bring ideas to life in the most exceptional and innovative ways.

Exploring Thermoplastics: Empowering Strength and Durability

Thermoplastics form the backbone of our 3D printing capabilities. Our customers have the chance to select from a variety of alternatives that boast great strength, durability, and a wide range of mechanical qualities thanks to the use of materials such as ABS, PLA, PETG, and nylon. Not only are these materials common, but they are also essential for the production of prototypes and functioning components that are up to the highest possible standards of accuracy and quality.

Revolutionizing with Resins: Achieving Unparalleled Details

Resin-based materials are at the heart of our commitment to achieving impeccable details and smooth surface finishes. Through technologies like stereolithography (SLA) and Digital Light Processing (DLP) 3D printing, we offer a wide range of material properties, including options for rigidity, flexibility, and transparency. These materials serve as a testament to our dedication to innovation and our relentless pursuit of delivering solutions that redefine what’s possible.

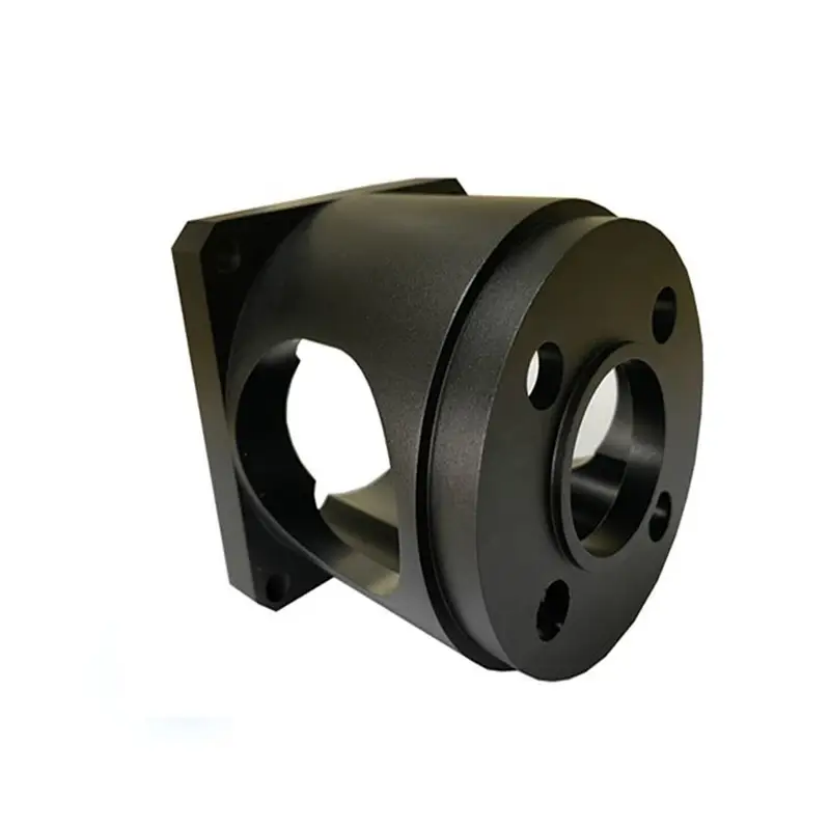

Elevating Precision with Metals: A Symphony of Strength

Our knowledge and experience in rapid prototyping extends to the field of metals, where we are able to capitalize on the potential offered by a variety of metal alloys. We are able to generate functional metal parts with unrivaled mechanical qualities by utilizing technologies such as Selective Laser Melting (SLM) and Direct Metal Laser Sintering (DMLS). Our commitment to excellence has not wavered, and as a result, we have cemented our position as industry pioneers in the field of rapid prototyping. Whether it’s aluminum, stainless steel, titanium, or brass, we always strive for excellence.

Conclusion

At CS Mold, innovation is more than just a buzzword; it’s a way of life. Our dedication to pushing the boundaries of what’s possible is reflected in our utilization of composite materials, silicone, and advanced ceramics for rapid prototyping. With our unwavering commitment to delivering solutions that surpass expectations, we continue to pave the way for a future where every idea has the potential to shape the world, one prototype at a time. For more information, please fill out the form or email us.