Welcome to CS Mold, your trusted partner in mold design and manufacturing. When it comes to molding processes, understanding the differences between compression vs transfer molding is crucial in making an informed decision for your project. In this article, we will explore the characteristics of both processes and help you determine which one is best suited to meet your specific needs.

Compression Molding

Compression molding is a widely used process that offers several advantages for various applications:

Material Placement: In compression molding, the raw material, typically in solid or pre-cut form, is placed directly into the mold cavity. This allows for flexibility in material selection and the use of various materials, including rubber compounds and thermosetting plastics.

Pressure Application: Pressure is applied directly to the material in the mold cavity, ensuring complete filling and uniform distribution. This process results in strong, void-free parts with excellent dimensional accuracy.

Cost-Effectiveness: Compression molding molds are generally simpler in design compared to other processes, making them cost-effective, especially for low to medium production volumes. The simplicity of the mold design also enables faster turnaround times and lower tooling costs.

Transfer Molding

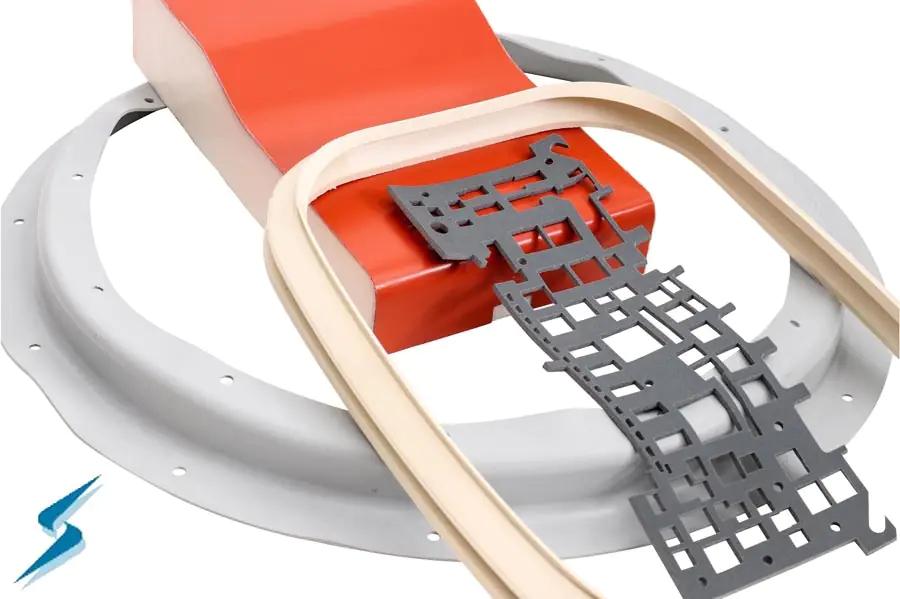

Transfer molding combines the best features of compression molding and injection molding, providing unique advantages for specific applications:

Material Preparation: In transfer molding, the raw material is preheated and softened or in a liquid state. It is placed in a chamber called the pot, ready for transfer.

Material Transfer: A plunger applies pressure to the material in the pot, forcing it to flow through runners and into the mold cavity. This controlled transfer ensures precise material distribution and eliminates concerns about material handling.

Complexity and Precision: Transfer molding is well-suited for parts with intricate designs or those requiring precise material flow control. It allows for the production of complex parts with consistent dimensional accuracy and excellent surface finish.

Conclusion

Choosing between compression molding and transfer molding is a critical decision that can impact the success of your project. CS Mold is here to assist you in making the right choice. With our expertise in mold design and manufacturing, we offer comprehensive solutions that meet the specific requirements of your project.

To discuss your project needs or to learn more about our molding services, we invite you to contact us. Simply fill out the form on our website or send us an email. Our dedicated team is ready to provide personalized solutions and help you achieve excellence in mold design and manufacturing.

Partner with CS Mold today and experience the difference our expertise can make in your molding projects. Contact us now to take the first step toward successful mold design and manufacturing.